Introduction to JIS Die Springs

If you’ve worked with molds or mechanical devices, you’ve probably encountered a crucial but often overlooked part: the die spring. Specifically, JIS die springs—heavy-duty compression coil springs conforming to the Japanese Industrial Standards (JIS)—are fundamental in the precision tooling and manufacturing industries. But what exactly are JIS die springs, and why should designers and engineers pay close attention?

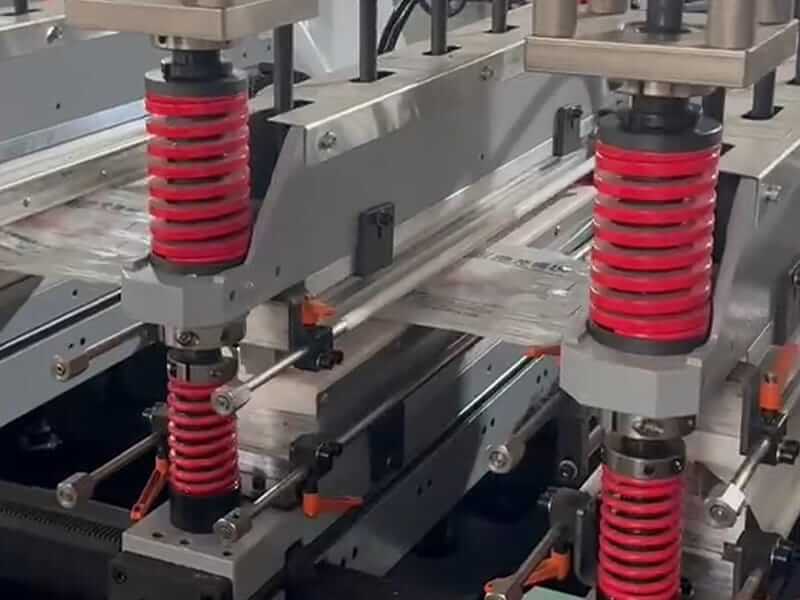

Simply put, a JIS die spring is a specialized compression spring designed to perform reliably in molds such as stamping dies, injection molds, and die-casting molds. Its dimensions, load rating, and color coding all follow the strict JIS standard, providing a consistent, reliable solution for high-load, long-life spring applications.

In this guide, brought to you by Dingli Spring, a trusted supplier of premium die springs, we will unpack everything you need to know—from the key characteristics and applications of JIS die springs to choosing the right one for your project.

What is a JIS Die Spring?

Definition and Core Purpose

- Heavy-duty compression coil spring meeting the JIS standard.

- Designed to apply ejection force to remove molded parts or scrap — preventing production jams.

- Provides resetting force that returns sliders, lifters, or slides to their initial position.

- Supplies pressing or holding force in tooling assemblies.

- Absorbs impact loads and vibrations during operations.

- Widely used in molds, automated machinery, and fixtures requiring consistent, high-load spring performance.

Why Japanese Standard?

The JIS standard ensures:

- Precise load ratings tied to spring specifications.

- Industry-wide color coding for spring classification.

- Standardized dimensions and tolerances for interchangeability.

- High reliability validated by strict performance requirements.

This allows users like Dingli Spring’s customers to quickly select the right springs with confidence and maintain efficient manufacturing processes.

Key Features of JIS Die Springs

1. High Load Capacity

JIS die springs support greater loads for the same size compared to ordinary compression springs. Thanks to premium alloys like chromium-silicon and chromium-vanadium steels combined with advanced heat treatments, these springs withstand rigorous industrial conditions without performance degradation.

2. Long Service Life

Engineered for millions or tens of millions of compression cycles, these springs resist fatigue and retain their mechanical properties—reducing costly downtime. Dingli Spring guarantees all JIS springs undergo rigorous quality controls ensuring long-lasting performance.

3. Color-Coded Load Classification

A hallmark of JIS die springs is their color coding system, denoting load capacity for quick identification:

| Color | Load Classification | Application Scenario |

|---|---|---|

| Brown | Heavy Load | High-strength molds, stamping dies |

| Green | Medium-Heavy Load | Heavy-duty injection molds and tooling |

| Blue | Medium Load | Standard die and mold applications |

| Red | Light-Medium Load | Delicate molds, lighter force requirements |

| Yellow | Light Load | Precision small parts and assemblies |

4. Standardized Dimensions & Precision

The JIS standard defines series of dimensions like inner/outer diameter, wire thickness, free length, and maximum compression stroke. This standardization streamlines replacement and compatibility. Springs undergo “setting” or static load treatment—a necessary step to eliminate residual stresses and ensure consistent load-bearing performance.

Overview of JIS Standard

The JIS standard outlines:

- Dimensional series applicable to die springs.

- Load classifications linked to color codes.

- Test methods for load, deflection, and fatigue.

- Marking conventions including color and tag placement.

- Requirements for treatment to enhance durability.

This makes JIS die springs some of the most trusted components in tooling globally and ensures compatibility with the ISO 10243 international standard—a fact leveraged by Dingli Spring to serve customers worldwide with compliant products.

Applications of JIS Die Springs

JIS die springs are pivotal to:

- Stamping and punching dies: Eject scrap and maintain die clearance.

- Injection molding: Eject parts and reset mold cores.

- Die casting molds: Absorb metal injection impact forces.

- Industrial machinery and automation: Provide reliable, high-force spring action in jigs and fixtures.

Dingli Spring supplies JIS-compliant springs optimized for all these industries, helping clients maximize production uptime.

How to Select the Right JIS Die Spring

- Assess Load Requirements:

Determine the maximum force needed and choose the corresponding color-coded spring grade. - Confirm Dimensions & Installation Space:

Ensure the spring’s outer and inner diameters plus free length fit mold design specs. - Determine Working Stroke:

Operating stroke should not exceed the allowable compression limit (varies by color). Over-compression reduces lifespan. - Consider Life Cycle Expectations:

Reference manufacturer-provided life charts to align compression ratio and cycle count. - Incorporate Guides:

Use guide rods or sleeves to reduce spring buckling and side loading.

Maintenance & Best Practices

- Schedule regular inspections to catch wear or corrosion early.

- Avoid compressing springs beyond approved limits to avoid permanent damage.

- Ensure clean installations with correct guiding components.

- Replace springs upon signs of reduced force or physical damage.

At Dingli Spring, we provide detailed technical advice and curated product lines to help you maintain optimal spring performance.

Conclusion

For demanding mold and tooling applications, JIS die springs represent the gold standard. They deliver uncompromising load capacity, longevity, and precise standardized sizing paired with an intuitive color coding system—making selection and replacement straightforward.

With Dingli Spring’s support, you get access to authentic, JIS-standard die springs that guarantee consistent performance and operational efficiency. Invest in the right spring today and reduce production disruptions tomorrow.

FAQs

Q1: What is a JIS die spring?

A heavy-duty compression spring conforming to Japanese Industrial Standards, used in dies and molds.

Q2: What do the colors of JIS die springs signify?

They represent load classification from heavy (brown) to light (yellow), helping quick selection.

Q3: Are JIS and ISO die springs interchangeable?

Generally yes, as standards are highly compatible regarding size and color coding.

Q4: Why avoid over-compressing JIS die springs?

Doing so risks damaging the spring, shortening lifetime drastically.

Q5: Which industries commonly use JIS die springs?

Stamping, injection molding, die casting, and automation machinery.

If you want more detailed support or a custom recommendation for your application, contact Dingli Spring — your reliable partner in premium JIS die springs.