Introduction: Why China Dominates the Global Spring Manufacturing Industry

Have you ever wondered why over 60% of the world’s industrial springs come from China? It’s not just about cost – though that’s certainly a factor. The real story behind China’s dominance in the compression spring manufacturing sector involves a complex mix of technological advancement, supply chain efficiency, and decades of specialized expertise.

When you’re sourcing custom compression springs for your business, choosing the right manufacturer can make or break your project. Whether you need springs for automotive applications, industrial machinery, or electronic devices, the stakes are high. A single batch of substandard springs can halt your production line, damage your reputation, and cost thousands in delays and replacements.

But here’s the thing: not all Chinese spring manufacturers are created equal. While companies like Cixi Dili Spring Co., Ltd., established since 1995, have built solid reputations through consistent quality and international certifications, others might leave you with springs that fail under pressure – literally.

So how do you separate the wheat from the chaff? What should you look for when evaluating potential compression spring suppliers in China? Let’s dive deep into the essential factors that will help you make an informed decision and avoid costly mistakes.

Understanding the Chinese Spring Manufacturing Landscape

The Scale and Scope of Chinese Spring Production

China’s spring manufacturing industry is massive, with over 3,000 registered manufacturers producing everything from tiny micro-springs for electronics to massive industrial compression springs for heavy machinery. The industry is primarily concentrated in three major regions:

- Zhejiang Province (including Cixi, Ningbo, and Wenzhou)

- Guangdong Province (Shenzhen, Dongguan, and Guangzhou)

- Jiangsu Province (Suzhou, Wuxi, and Nanjing)

Each region has its specialties. For instance, Zhejiang Province, where Cixi Dili Spring Co., Ltd. is located, is renowned for its high-precision mold springs and automotive components. This regional specialization means that choosing a manufacturer from the right area can give you access to deeper expertise and better supply chains.

Types of Compression Springs Available from Chinese Manufacturers

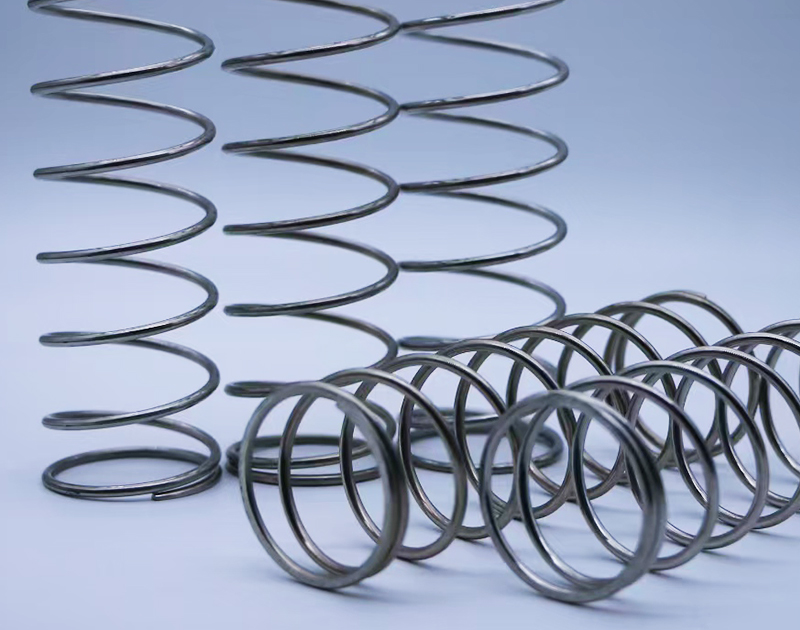

Chinese manufacturers typically offer several categories of compression springs:

- Standard compression springs (following DIN, JIS, ISO standards)

- Heavy-duty industrial springs (for mining, construction equipment)

- Precision micro-springs (for electronics, medical devices)

- Hot-wound compression springs (for high-temperature applications)

- Variable pitch springs (for specialized load requirements)

- Conical and barrel-shaped springs (for specific space constraints)

Understanding which type you need is crucial before beginning your supplier search. A manufacturer specializing in heavy-duty springs might not be the best choice for precision electronic components, and vice versa.

Key Quality Indicators to Look For

1. International Certifications and Standards Compliance

Think of certifications as a manufacturer’s report card. They’re not just pieces of paper – they represent rigorous third-party validation of quality systems and processes. Here’s what to look for:

Essential Certifications:

- ISO 9001:2015 – Quality Management System

- IATF 16949 – Automotive Quality Management (if you’re in automotive)

- ISO 14001 – Environmental Management System

- RoHS Compliance – For export to EU markets

- REACH Compliance – Chemical safety standards

A reputable manufacturer like Cixi Dili Spring Co., Ltd. will readily provide certification documents and maintain current registrations. Be wary of suppliers who are vague about their certifications or provide outdated documents.

2. Material Quality and Sourcing

The performance of your compression springs starts with the raw materials. Chinese manufacturers typically work with various spring steels:

- Music wire (ASTM A228) – For high-stress applications

- Stainless steel (302/304/316) – For corrosion resistance

- Chrome silicon – For elevated temperatures

- Chrome vanadium – For fatigue resistance

- Inconel/Monel – For extreme environments

Ask potential suppliers about their material sourcing. Do they use certified steel from reputable mills? Can they provide material test certificates (MTCs)? A quality manufacturer will have established relationships with trusted steel suppliers and maintain strict incoming material inspection protocols.

3. Manufacturing Capabilities and Equipment

Modern spring manufacturing requires sophisticated equipment. Here’s what to evaluate:

CNC Coiling Machines:

- Look for manufacturers using Japanese (like CNC spring forming machines from Japan) or European equipment

- Multi-axis capabilities for complex geometries

- Precision tolerance control (±0.01mm for critical dimensions)

Heat Treatment Facilities:

- In-house stress relieving ovens

- Controlled atmosphere furnaces for consistent results

- Temperature monitoring and recording systems

Surface Treatment Options:

- Black oxide coating (发黑) – Provides mild corrosion resistance and reduces light reflection

- Oil coating (上油) – Prevents rust during storage and shipping

- Zinc plating – Enhanced corrosion protection

- Nickel plating – For decorative and protective purposes

- Passivation – For stainless steel springs

- Powder coating – For heavy-duty applications

Cixi Dili Spring Co., Ltd. offers comprehensive surface treatment options including oil coating and black oxide treatment, ensuring your compression springs are protected during storage and suitable for their intended applications.

Technical Capabilities and Engineering Support

Drawing Verification and Compliance Testing

When evaluating Chinese manufacturers, it’s important to understand the different levels of engineering support available. There are generally two types of manufacturers:

- Full-design capability manufacturers – Can create springs from concept

- Precision manufacturing specialists – Excel at producing springs to exact customer specifications

Many successful manufacturers, including Cixi Dili Spring Co., Ltd., specialize in the second category. Here’s what this means for you:

Engineering Verification Services:

- Drawing analysis – Review your technical drawings for manufacturability

- Specification validation – Ensure your requirements match industry standards

- Load and rate calculations – Verify that specified springs will meet performance requirements

- Tolerance assessment – Confirm that dimensional requirements are achievable

- Material recommendation – Suggest optimal materials based on your application

What This Approach Offers:

- Accuracy assurance – Your designs are checked against manufacturing capabilities

- Cost optimization – Identify potential cost savings without compromising quality

- Risk reduction – Catch potential issues before production begins

- Faster turnaround – No design phase means quicker move to production

- Your IP protection – You maintain complete control over your designs

This focused approach actually benefits many customers who already have proven designs or work with their own engineering teams. You get specialized manufacturing expertise without paying for design services you don’t need.

Working with Customer Specifications

The best manufacturers excel at translating your specifications into reality. Here’s what to provide for optimal results when ordering custom springs:

Essential Drawing Information:

- Wire diameter and tolerance

- Free length and solid height

- Number of active and total coils

- Spring rate or load requirements

- End type configuration

- Surface treatment requirements

Additional Helpful Information:

- Operating environment (temperature, chemicals, moisture)

- Cycle life requirements

- Assembly constraints

- Packaging preferences

Professional manufacturers like Cixi Dili Spring Co., Ltd. will review your drawings thoroughly and ask clarifying questions to ensure perfect execution. This collaborative approach often reveals opportunities for optimization that can save costs or improve performance.

Production Capacity and Lead Times

Understanding Manufacturing Scale

Size matters, but bigger isn’t always better. Consider these factors:

For Large Volume Orders (100,000+ pieces):

- Look for manufacturers with multiple production lines

- Automated quality inspection systems

- Large warehouse facilities

- Established logistics partnerships

For Small to Medium Volumes (1,000-50,000 pieces):

- Flexible production scheduling

- Quick changeover capabilities

- Willingness to hold inventory

- Competitive pricing for smaller batches

Realistic Lead Times and Planning

Chinese manufacturers typically quote lead times of 15-30 days for custom springs, but several factors affect actual delivery:

- Design complexity – Simple designs ship faster

- Material availability – Special alloys may require longer sourcing

- Surface treatment – Black oxide and oil coating add 2-3 days

- Quality inspection – Comprehensive testing takes time

- Shipping method – Sea freight (30-45 days) vs air freight (7-10 days)

Be skeptical of suppliers promising unrealistically fast turnarounds for custom products. Quality manufacturing takes time, and rushed production often leads to quality issues.

Quality Control and Testing Procedures

In-Process Quality Control

Quality isn’t just about final inspection – it’s built into every step of manufacturing. Look for manufacturers implementing:

Statistical Process Control (SPC):

- Real-time monitoring of critical dimensions

- Control charts for process stability

- Corrective action protocols

- Continuous improvement programs

Stage Inspections:

- Incoming material verification

- First article inspection

- In-process dimensional checks

- Pre-shipment inspection

Testing Capabilities

A comprehensive testing lab should include:

Dimensional Testing:

- Optical comparators for precision measurement

- Coordinate Measuring Machines (CMM)

- Digital micrometers and calipers

- Profile projectors

Performance Testing:

- Load testing equipment

- Fatigue testing machines

- Spring rate verification

- Compression set testing

- Salt spray testing for corrosion resistance

Documentation:

- Detailed inspection reports

- Compliance certificates

- Test data and charts

- Traceability records

Cixi Dili Spring Co., Ltd. maintains a full testing laboratory with equipment calibrated to international standards, ensuring every batch meets specified requirements before shipping.

Pricing Strategies and Cost Considerations

Understanding Chinese Pricing Models

Chinese compression spring manufacturers typically price based on:

- Material costs (usually 40-50% of total cost)

- Processing complexity (setup time, special operations)

- Order volume (economies of scale)

- Surface treatment (black oxide or oil coating adds 5-10% to base cost)

- Packaging requirements (standard vs custom)

- Payment terms (T/T, L/C, etc.)

Hidden Costs to Consider

The quoted price isn’t always the total cost. Factor in:

- Tooling charges for custom specifications

- Sample fees (often refundable with orders)

- Inspection costs (third-party if required)

- Freight and insurance

- Import duties and taxes

- Currency fluctuation risks

Getting the Best Value

Rather than simply choosing the lowest bidder, consider:

- Total Cost of Ownership (TCO) including potential failure costs

- Volume discount structures for long-term partnerships

- Payment term flexibility (30/70, 50/50, etc.)

- Free sample policies for testing

- Warranty terms and defect handling procedures

Communication and Customer Service Excellence

Language and Cultural Considerations

Effective communication is crucial for successful partnerships. Evaluate:

Language Capabilities:

- English proficiency of sales and technical teams

- Availability of native speakers for complex discussions

- Quality of written documentation and specifications

Response Times:

- Email response within 24 hours

- Real-time communication options (WeChat, WhatsApp)

- Technical query resolution speed

- Time zone accommodation for urgent matters

Project Management and Updates

Professional manufacturers provide:

- Dedicated project managers for your account

- Regular production updates with photos

- Proactive communication about potential delays

- Clear escalation paths for issues

- Detailed shipping documentation

Red Flags: What to Avoid

Warning Signs of Unreliable Suppliers

Watch out for manufacturers who:

- Refuse factory visits or video tours

- Can’t provide verifiable certifications

- Offer prices significantly below market rates

- Demand 100% upfront payment

- Have no online presence or professional website

- Can’t provide references from existing customers

- Show inconsistent communication or frequent staff changes

- Rush you to place orders without proper evaluation

- Claim to design everything but can’t show original work

- Promise unrealistic capabilities beyond their equipment

Common Scams and How to Avoid Them

- Bait and switch – Samples don’t match production quality

- Material substitution – Using cheaper alloys than specified

- Ghost factories – Trading companies posing as manufacturers

- Certification fraud – Fake or expired certificates

Always verify suppliers through multiple channels: company registration checks, factory audits (virtual or in-person), and reference checks with existing customers.

Building Long-term Partnerships with Chinese Spring Manufacturers

The Value of Relationship Building

In Chinese business culture, relationships (关系 or “guanxi”) matter tremendously. Investing in relationship building yields:

- Better pricing for loyal customers

- Priority production scheduling during busy periods

- Flexibility on minimum order quantities

- Access to new technologies and capabilities

- Improved payment terms over time

Strategic Partnership Development

Consider these strategies for long-term success:

- Start small with trial orders before committing to large volumes

- Visit the factory at least once to build face-to-face relationships

- Provide accurate forecasts to help suppliers plan capacity

- Pay on time to build trust and credibility

- Share feedback constructively for continuous improvement

- Consider exclusive agreements for critical components

The Advantage of Specialized Manufacturers

Working with manufacturers who focus on production excellence rather than trying to be everything to everyone often yields better results. Companies like Cixi Dili Spring Co., Ltd. have perfected their manufacturing processes over decades, ensuring:

- Consistent quality through refined processes

- Competitive pricing from operational efficiency

- Reliable delivery from focused production planning

- Clear communication about capabilities and limitations

Conclusion: Making the Right Choice for Your Business

Choosing the right compression spring manufacturer in China isn’t just about finding the lowest price – it’s about finding a partner who can consistently deliver quality products, provide technical support, and grow with your business.

Companies like Cixi Dili Spring Co., Ltd., with nearly three decades of experience since 1995, demonstrate the level of expertise and reliability you should seek. Their focused approach – specializing in precise manufacturing to customer specifications with comprehensive surface treatments including oil coating and black oxide – represents a proven model for success in Chinese spring manufacturing.

Remember, the right supplier will:

- Welcome your technical drawings and provide honest feedback about manufacturability

- Offer transparency in their processes and capabilities

- Demonstrate expertise in producing springs to your exact specifications

- Provide competitive pricing without compromising quality

- Support you with reliable quality control and testing

Take your time to evaluate potential suppliers thoroughly. Request samples based on your drawings, check references, and if possible, arrange a factory visit. The effort you invest in supplier selection will pay dividends in product quality, reliability, and peace of mind.

Whether you need standard compression springs or complex custom designs based on your engineering drawings, China’s manufacturing ecosystem offers tremendous opportunities – if you know what to look for and choose wisely.

About Cixi Dili Spring Co., Ltd.

Established in 1995, Cixi Dili Spring Co., Ltd. has been a trusted partner for global businesses seeking high-quality spring solutions. Specializing in compression springs, mold springs (JIS & US standard), torsion springs, extension springs, and custom-shaped springs, we excel at transforming your technical drawings into precision-manufactured springs.

Our engineering team carefully reviews customer drawings to ensure manufacturability and optimal performance. With comprehensive surface treatment options including oil coating and black oxide treatment, we protect your springs from corrosion while meeting your specific application requirements.

From automotive and electronics to industrial machinery and consumer products, our springs power applications worldwide. We combine nearly 30 years of manufacturing expertise with modern equipment and strict quality control to deliver springs that meet international standards.

Ready to discuss your compression spring specifications? Send us your drawings for evaluation:

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004

Let’s work together to transform your spring specifications into reliable, high-quality products you can count on.

Frequently Asked Questions (FAQs)

Q1: What’s the typical minimum order quantity (MOQ) for custom compression springs from Chinese manufacturers?

A: MOQs vary significantly depending on the manufacturer and spring specifications. For standard designs, MOQs can be as low as 1,000 pieces. For custom designs based on your drawings, MOQs typically range from 5,000 to 10,000 pieces. However, established manufacturers like Cixi Dili Spring Co., Ltd. often show flexibility for prototype orders or high-value customers, sometimes accepting orders as small as 500 pieces for an additional setup fee. The complexity of your specifications and the wire diameter also affect MOQ requirements.

Q2: How can I verify that a Chinese spring manufacturer is legitimate and not a trading company?

A: There are several verification methods: Request a business license and check it against Chinese government databases. Ask for detailed factory photos and videos showing production equipment with your company name visible. Look for manufacturers who are transparent about their capabilities – legitimate manufacturers like Cixi Dili Spring Co., Ltd. will clearly state what they can and cannot do, such as focusing on manufacturing to customer drawings rather than claiming full design capabilities. Use third-party verification services like SGS or Bureau Veritas. Most importantly, legitimate manufacturers will welcome factory visits and have established production facilities with permanent equipment installations.

Q3: What surface treatments are most suitable for compression springs in different environments?

A: The choice of surface treatment depends on your application environment. Oil coating is excellent for temporary rust prevention during shipping and storage, and it’s cost-effective for springs used in dry, indoor environments. Black oxide coating provides mild corrosion resistance and is ideal when you need to reduce light reflection or want a professional appearance. Zinc plating offers better corrosion resistance for moderate outdoor exposure. Nickel plating provides both corrosion resistance and an attractive finish. For harsh environments, consider passivation for stainless steel springs. Manufacturers like Cixi Dili Spring Co., Ltd. can recommend the most suitable treatment based on your specific application requirements.

Q4: If a manufacturer can’t design springs from scratch, should I look elsewhere?

A: Not necessarily! In fact, manufacturers who specialize in precise execution of customer drawings often provide superior results for many businesses. Here’s why: They’ve perfected their manufacturing processes through focused specialization. They typically offer better pricing since you’re not paying for design services you don’t need. They’re often more transparent about capabilities and limitations. Your intellectual property remains completely under your control. Companies like Cixi Dili Spring Co., Ltd. excel at reviewing your drawings for manufacturability and suggesting optimizations while maintaining your design intent. This approach is ideal if you have in-house engineering or work with design consultants who understand your application requirements.

Q5: What information should I include when sending drawings to Chinese spring manufacturers for quotation?

A: To receive accurate quotations and ensure smooth production, include: Complete dimensional specifications (wire diameter, outer/inner diameter, free length, solid height). Material requirements (specific grade or general properties needed). Quantity needed (both initial order and annual forecast if available). Surface treatment requirements (oil coating, black oxide, plating, etc.). Tolerance requirements for critical dimensions. Load or spring rate specifications if applicable. End type configuration (closed, ground, squared, etc.). Operating environment details (temperature range, chemical exposure, indoor/outdoor use). Any special packaging requirements. The more detailed your specifications, the more accurate the quotation and the smoother the production process. Professional manufacturers will ask clarifying questions if any information is missing.