Introduction: The Dawn of a New Era in Sustainable Manufacturing

When you think about spring manufacturing, what comes to mind? Precision engineering? Quality control? International standards compliance? While these elements remain fundamental to our operations at Cixi Dili Spring Co., Ltd., we’ve added another crucial dimension to our manufacturing philosophy: environmental stewardship through renewable energy adoption.

The manufacturing industry stands at a critical juncture. How do we balance the demands of continuous production with our responsibility to the planet? How can we maintain competitive pricing while investing in sustainable infrastructure? These questions drove us to embark on an ambitious solar energy project that would transform not just our factory’s rooftop, but our entire approach to production sustainability.

In late 2023, we completed the installation of a comprehensive 5,000 square meter photovoltaic system across our factory rooftops. This wasn’t merely an infrastructure upgrade—it represented a fundamental shift in how we power our operations, serve our customers, and contribute to the global push toward carbon neutrality. With an annual generation capacity of approximately 1,000,000 kWh, this solar array has become the beating heart of our green manufacturing initiative.

The Vision Behind the Panels: Why Solar, Why Now?

The decision to invest in solar energy didn’t happen overnight. As a company established in 1995, we’ve witnessed firsthand the evolution of manufacturing practices and the growing importance of sustainable production methods. Our clients—ranging from automotive manufacturers to electronics producers—increasingly prioritize suppliers who demonstrate genuine commitment to environmental responsibility.

But why did we choose rooftop solar specifically? The answer lies in the elegant simplicity of the solution. Our factory buildings, like many industrial facilities worldwide, feature vast, underutilized rooftop spaces. These areas, exposed to consistent sunlight throughout the year, represented dormant potential. By transforming these spaces into energy-generating assets, we could achieve multiple objectives simultaneously:

- Maximize existing infrastructure without requiring additional land acquisition

- Generate clean energy directly at the point of consumption

- Reduce dependency on grid electricity and fossil fuel sources

- Create a visible commitment to sustainability that resonates with stakeholders

- Establish energy independence that ensures production continuity

The timing proved equally strategic. Solar panel technology has matured significantly, offering improved efficiency rates and longer operational lifespans. Government incentives for renewable energy adoption, combined with decreasing installation costs, created an optimal investment window. Moreover, the global push toward carbon neutrality meant that early adoption would position us advantageously in an increasingly eco-conscious marketplace.

Technical Excellence: Engineering a 5,000 m² Solar Solution

The technical implementation of our solar project required meticulous planning and precision engineering—qualities that align perfectly with our core competencies in spring manufacturing. Working with leading solar technology providers, we designed a system that would seamlessly integrate with our existing infrastructure while maximizing energy generation potential.

Our 5,000 square meter installation comprises high-efficiency monocrystalline solar panels, selected for their superior performance characteristics and durability. These panels, arranged in optimized configurations across multiple rooftop sections, capture solar radiation even during partially cloudy conditions. The system incorporates advanced inverter technology that converts DC power to AC with minimal energy loss, ensuring maximum utilization of generated electricity.

The mounting structure deserves special attention. Given that our factory operates heavy machinery producing various spring types—from JIS standard mold springs to custom torsion springs—vibration management became a critical consideration. We implemented specialized mounting systems that isolate the solar panels from building vibrations while maintaining structural integrity under various weather conditions. This engineering approach reflects our broader philosophy: every component, whether a precision spring or a solar panel mount, must meet exacting standards.

Integration with our existing electrical infrastructure required careful coordination. We installed smart grid technology that enables real-time monitoring of energy generation, consumption patterns, and grid interaction. This system automatically prioritizes solar power usage during peak generation hours while seamlessly switching to grid power when necessary, ensuring uninterrupted production flow.

Safety considerations influenced every aspect of the design. Fire-resistant materials, lightning protection systems, and maintenance walkways ensure that our solar installation meets international safety standards including IEC 61215 for photovoltaic modules and IEC 62446 for grid-connected systems. Regular inspection protocols, developed in consultation with safety experts, maintain system integrity while protecting our workforce.

The Numbers Tell the Story: 2024 Performance Data and Analysis

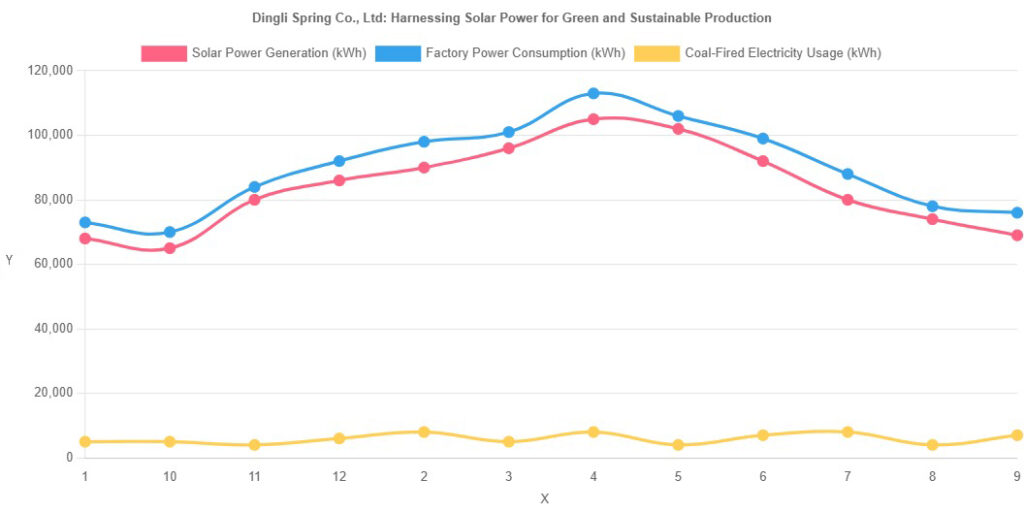

[Data Visualization: Solar Power Generation, Factory Power Consumption, and Coal-Fired Electricity Usage Chart – 2024 Annual Data]

The true measure of any industrial investment lies in its performance data. Throughout 2024, our first full year of solar operation, we meticulously tracked energy generation, consumption patterns, and the changing composition of our energy mix. The results exceeded our initial projections and validated the investment decision.

Our solar array generated approximately 1,000,000 kWh during 2024, with generation patterns closely following seasonal variations. Peak generation occurred during the April through September period, when longer daylight hours and optimal sun angles maximized panel efficiency. Even during winter months, the system maintained substantial generation capacity, contributing significantly to our energy needs.

The impact on our energy mix proved transformative. Prior to solar installation, our factory relied entirely on grid electricity, predominantly sourced from coal-fired power plants. The 2024 data reveals a dramatic shift: solar energy now accounts for a substantial portion of our total consumption, with coal-fired electricity usage declining proportionally. This transition didn’t compromise our production capacity—in fact, the stable energy supply enhanced operational consistency.

Monthly analysis reveals interesting patterns. During summer months, solar generation often exceeded our immediate consumption needs during peak daylight hours. This excess energy, initially fed back to the grid, laid the groundwork for our 2025 green energy sales program. Conversely, during high-production periods coinciding with lower solar generation, the hybrid system ensured seamless energy availability without production interruptions.

The financial implications prove equally compelling. While the initial investment required substantial capital allocation, the operational savings became apparent within months. Reduced grid electricity purchases, combined with favorable feed-in tariffs for excess generation, accelerated our return on investment timeline. Conservative projections suggest full investment recovery within 5-7 years, after which the system will generate pure profit through energy savings and sales.

Sustainable Production: How Green Energy Transforms Manufacturing Operations

The integration of solar energy into our manufacturing processes extends far beyond simple electricity substitution. It has fundamentally transformed how we approach production planning, quality assurance, and customer value propositions.

Consider the production of precision compression springs, one of our core product lines. These springs, manufactured to exacting tolerances for automotive and industrial applications, require consistent power supply for CNC coiling machines, heat treatment furnaces, and quality testing equipment. Previously, power fluctuations or grid instabilities could impact production schedules and potentially affect product quality. With our solar-supplemented energy system, we’ve achieved unprecedented power stability.

The environmental benefits cascade through our entire operation. Reduced carbon emissions from our manufacturing processes enable us to offer customers products with lower embedded carbon footprints. This advantage proves particularly valuable for clients pursuing their own sustainability goals or requiring suppliers to demonstrate environmental compliance. We can now provide detailed carbon accounting for our products, tracing energy sources through each manufacturing stage.

Employee morale and recruitment have benefited unexpectedly from our solar initiative. Workers express pride in contributing to sustainable manufacturing, and our green credentials attract environmentally conscious talent. The visible solar panels serve as daily reminders of our commitment to responsible production, fostering a culture of sustainability that extends beyond energy use to waste reduction, material efficiency, and process optimization.

Our quality management systems, certified to ISO 9001 standards, now incorporate energy source tracking as a parameter. This integration allows us to correlate product quality metrics with energy supply characteristics, providing insights that drive continuous improvement. For instance, we’ve observed that stable solar power during critical heat treatment processes yields more consistent spring properties, enhancing product reliability.

The 2025 Milestone: From Self-Sufficiency to Energy Provider

As we entered 2025, our solar energy project reached a significant milestone: the transition from energy self-sufficiency to becoming a net energy provider. This evolution represents more than just selling excess electricity—it symbolizes our transformation from a traditional manufacturer to an active participant in the renewable energy economy.

The decision to sell excess green electricity emerged from careful analysis of our generation and consumption patterns. During optimal generation periods, particularly weekend days when production scales back, our solar array generates substantial surplus energy. Rather than allowing this clean energy to go unutilized, we established agreements with the local grid operator to feed excess power into the regional network.

This arrangement provides multiple benefits. Financially, it creates an additional revenue stream that further improves our solar investment returns. Environmentally, it contributes clean energy to the regional grid, multiplying our positive impact beyond our factory walls. Strategically, it positions Cixi Dili Spring Co., Ltd. as a progressive manufacturer aligned with national renewable energy objectives.

The technical infrastructure supporting energy sales required additional investment in bi-directional metering and grid synchronization equipment. These systems ensure that power quality meets grid standards while accurately tracking energy flows for billing purposes. Our operations team underwent specialized training to manage this dual role as energy consumer and provider, developing competencies that enhance our technical capabilities.

Customer response to our energy provider status has been overwhelmingly positive. Many clients view it as evidence of our long-term stability and forward-thinking approach. Some have even inquired about potential partnerships for their own renewable energy initiatives, opening doors for deeper collaborative relationships beyond traditional supplier-customer dynamics.

Beyond Energy: The Broader Impact on Spring Manufacturing Excellence

While the immediate benefits of our solar installation center on energy and sustainability, the project’s influence extends throughout our manufacturing ecosystem. The discipline required for successful solar integration has enhanced our operational excellence across all areas.

In our mold spring division, where we produce JIS and US standard springs for injection molding and stamping applications, the stable power supply has enabled us to maintain tighter tolerances and more consistent heat treatment cycles. This improvement directly translates to enhanced product performance and extended service life—critical factors for customers operating high-speed production equipment.

Our custom spring development process has also benefited. The cost savings from reduced energy expenses have been partially redirected to R&D investments, enabling us to expand our engineering capabilities. We’ve acquired advanced simulation software and testing equipment that allow us to prototype and validate custom spring designs more efficiently. Whether developing specialized torsion springs for automotive applications or unique extension springs for industrial machinery, we can now offer faster development cycles and more innovative solutions.

The solar project has strengthened our position in international markets. European and North American customers, particularly those in countries with stringent environmental regulations, increasingly prefer suppliers demonstrating genuine sustainability commitment. Our solar-powered production provides tangible evidence of this commitment, facilitating market entry and customer retention in environmentally conscious regions.

Quality control processes have evolved to incorporate energy efficiency metrics. We now track energy consumption per unit produced across different product lines, identifying opportunities for process optimization. This data-driven approach has revealed surprising insights—for instance, certain spring winding sequences consume significantly less energy while maintaining identical quality outcomes. These discoveries drive continuous improvement initiatives that benefit both sustainability and profitability.

Looking Forward: The Future of Green Manufacturing at Dingli Spring

Our solar energy journey represents just the beginning of our sustainability transformation. Looking ahead, we envision multiple pathways for expanding our renewable energy capabilities and environmental stewardship.

Energy storage systems represent the logical next step. By installing industrial-scale battery storage, we could capture excess solar generation for use during non-daylight hours, further reducing grid dependency. Preliminary assessments suggest that combining our existing solar array with appropriate storage capacity could achieve near-complete energy independence for standard operations.

We’re exploring opportunities to extend solar installations to additional facility areas, including parking structures and auxiliary buildings. These expansions could increase our generation capacity by an estimated 30-40%, providing additional energy for expanded production capabilities or increased sales to the grid.

Collaboration opportunities continue to emerge. Several customers have expressed interest in joint sustainability initiatives, potentially including shared investments in renewable energy projects or collaborative carbon reduction programs. These partnerships could create value chains where sustainable practices multiply through connected operations.

Conclusion: A Model for Sustainable Spring Manufacturing

The transformation of our factory rooftops from passive structures to active energy generators exemplifies the potential for sustainable manufacturing in the 21st century. Through careful planning, strategic investment, and unwavering commitment to environmental responsibility, we’ve demonstrated that industrial operations can thrive while minimizing environmental impact.

Our 5,000 square meter solar array, generating 1,000,000 kWh annually, powers not just our machinery but our vision for the future. It enables year-round production stability, reduces operational costs, and positions us as a preferred partner for environmentally conscious customers worldwide. More importantly, it proves that traditional manufacturing companies can successfully evolve into sustainable enterprises without compromising product quality or customer service.

As we continue producing high-quality springs—from precision mold springs meeting JIS and DIN standards to custom-designed torsion and compression springs for specialized applications—we do so with the knowledge that our energy comes from the sun above rather than fossil fuels below. This transformation reflects our broader commitment to excellence in all aspects of operation, from engineering and production to environmental stewardship.

The journey from roof to reality required vision, investment, and determination. Yet the results—measured in reduced emissions, energy independence, and enhanced market position—validate every decision along the way. We invite customers, partners, and fellow manufacturers to join us in embracing sustainable production methods that benefit business, society, and the planet.

For organizations considering similar renewable energy initiatives, our experience offers valuable lessons: start with clear objectives, invest in quality technology, integrate systems thoughtfully, and maintain focus on long-term value creation. The path to sustainability may require initial investment and effort, but the returns—financial, environmental, and reputational—make the journey worthwhile.

About Cixi Dili Spring Co., Ltd.

Established in 1995, Cixi Dili Spring Co., Ltd. has evolved from a traditional spring manufacturer into a forward-thinking enterprise combining technical excellence with environmental responsibility. Our comprehensive product portfolio encompasses mold springs (JIS and US standards), torsion springs, compression springs, extension springs, music wire springs, and custom-shaped springs for diverse industrial applications.

Our commitment to quality extends beyond product specifications to encompass every aspect of operation, including our pioneering adoption of renewable energy. With complete R&D, production, and sales capabilities, we serve global markets while maintaining strict adherence to international standards including JIS, DIN, ANSI, and ISO specifications.

We specialize in custom spring development, working from customer samples or drawings to create optimized solutions for specific applications. Our solar-powered facility ensures sustainable production while maintaining the highest quality standards our customers expect. Learn more about our company and capabilities.

Connect with Us

Ready to explore how sustainable spring manufacturing can benefit your operations?

Contact us to discuss your requirements:

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004

Visit our solar-powered facility and see firsthand how renewable energy and precision engineering combine to create superior spring solutions for the modern world.

Frequently Asked Questions

Q1: How does solar power generation affect the quality and consistency of your spring products?

Solar power actually enhances our product quality and consistency. The stable, clean electricity eliminates power fluctuations that could impact sensitive manufacturing processes like heat treatment and CNC coiling. Our quality data from 2024 shows improved consistency metrics across all product lines since implementing solar power. Additionally, the cost savings from reduced energy expenses have been reinvested in advanced quality control equipment, further enhancing our capabilities.

Q2: Can you provide carbon footprint data for springs manufactured using solar energy?

Yes, we can provide detailed carbon footprint calculations for all our products. Our energy monitoring systems track the exact energy source (solar vs. grid) used during each production stage. This allows us to calculate precise carbon emissions per unit produced. For springs manufactured primarily during peak solar generation hours, carbon footprints can be reduced by up to 60-70% compared to traditional grid-powered production. We provide this data as part of our environmental compliance documentation for customers requiring sustainability metrics.

Q3: What happens to your production during extended cloudy periods or at night?

Our hybrid energy system ensures uninterrupted production regardless of weather conditions or time of day. During periods of low solar generation, we seamlessly transition to grid electricity without any impact on production schedules or quality. The grid connection acts as a reliable backup, while our solar system reduces overall grid dependence. In 2024, even during the cloudiest winter months, solar still contributed 20-30% of our energy needs, with the grid providing the balance.

Q4: How has the solar installation affected your pricing and competitiveness?

The solar installation has enhanced our competitiveness without increasing customer prices. Reduced energy costs allow us to maintain stable pricing despite inflation in other areas. For long-term contracts, we can offer price stability guarantees partly due to predictable energy costs. Moreover, our green credentials often provide a competitive advantage when customers evaluate suppliers based on sustainability criteria, sometimes allowing us to win contracts even when not the lowest bidder.

Q5: Can you accommodate customers who specifically want their products manufactured using renewable energy?

Absolutely. We can schedule production runs during peak solar generation periods for customers requiring 100% renewable energy manufacturing. Our production planning system can allocate solar-powered time slots for specific orders, and we provide certification documenting the renewable energy usage. This service particularly appeals to customers with strict sustainability requirements or those seeking to reduce their Scope 3 emissions. Contact us to discuss how we can align our solar-powered production schedules with your sustainability objectives.