Why the Spring Defines Your Gripper’s Success

Let’s be blunt: for a hand gripper, everything comes back to the spring. The spring determines the squeeze profile, user perception of “smoothness,” expected life, and long-term warranty costs. Many manufacturers historically default to round wire extension springs because they’re familiar and cheap. But when your customer base expects subtle increments of resistance, repeatable feel across lots, and low field-failure rates, the spring is the first place to optimize.

What B2B fitness OEMs care about (and what they lose with the wrong spring)

- Consistent resistance across thousands of cycles — trainers and consumers test gear hard.

- Linear / predictable force curve — customers notice jumps, dips, or non-linear feel immediately.

- Low variability between parts — to protect brand reputation and reduce returns.

- Aesthetic and brand options — many OEMs use color-coded springs to indicate resistance levels.

Rectangular-section springs were developed to solve these specific problems — not merely to be “different.” For grippers, the geometry itself changes how the spring bends, compresses, and distributes stress.

Rectangular Springs: A Game-Changer for Hand Grippers

When designed and produced to strict quality controls, rectangular springs offer three tangible advantages that matter to OEM manufacturers:

Higher force density

Because rectangular sections have a higher second moment of area in the bending direction, you can achieve more squeeze force with less material or smaller overall spring dimensions — a key advantage when fitting into compact gripper designs.

Improved buckling resistance

Rectangular cross-sections resist sideways bending better than round wires of similar cross-sectional area. The result: fewer manufacturing rejects and a more stable, repeatable product in the hands of users.

Smoother, more linear force curve

Properly heat-treated rectangular springs can provide a linear or intentionally progressive resistance profile — far more controllable than many round-wire extension springs.

Practical benefits to your production line

- Fewer rejects and reworks — tighter tolerances reduce assembly headaches.

- Easier lot-to-lot matching — consistent metallurgy and heat treatment yield predictable results.

- Less warranty exposure — improved fatigue life means fewer in-field failures.

- Brand differentiation — choose colored coatings for resistance tiers and create a recognizable product line.

Materials That Matter: 55CrSi, 50CrVA, 65Mn

Choosing the right alloy and heat treatment is equally important to cross-section geometry. For high-performance hand grippers we typically recommend one of the following, depending on target feel and production volume:

55CrSi

55CrSi is a high-strength spring steel with good fatigue resistance after proper heat treatment and tempering. It’s a great general-purpose choice when you need a balance of cost, formability, and cycle life.

50CrVA

50CrVA (a chromium-vanadium spring steel) offers higher toughness and good resistance to shock loading. It’s an excellent pick for OEMs targeting premium feel and slightly higher fatigue life in small-dimension rectangular sections.

65Mn

65Mn (also commonly used in springs) provides excellent elastic limit and fatigue characteristics when properly processed. When your design requires maximum energy storage in a compact form factor, 65Mn is a reliable option.

How material choice maps to product tiers

- Entry-level mass market: 55CrSi — cost-effective and reliable.

- Mid-tier / premium: 50CrVA — improved toughness and consumer-perceived quality.

- Performance / competition: 65Mn — best for maximum force density in compact parts.

Production & Process: From Drawing to Batch-Ready Springs

We don’t just bend steel and ship it. Reliable rectangular springs require a controlled production sequence to guarantee repeatable results. Key production controls include:

- Precision forming: Accurate roll/form dies to create consistent rectangular cross-sections without introducing micro-cracks.

- Controlled heat treatment: Atmosphere-controlled tempering to reach target tensile and yield properties while minimizing scale and decarburization.

- Shot-peening / surface finishing: To increase fatigue life and enable colored coatings to adhere consistently.

- Lot-level testing: Cycle testing, load-deflection sampling, and visual inspection per batch.

JIS Compliance — why we highlight JIS

Many of our international customers require compliance with recognized engineering standards. For springs intended for mechanical assemblies, adherence to recognized standards (such as those from JIS) ensures consistent dimensioning, material traceability, and predictable mechanical behavior. We design our rectangular springs to align with relevant JIS guidance for spring materials, tolerances, and test methods — this gives OEMs confidence when integrating our parts into their production lines.

Note: We reference JIS-based practices and test methods in our quality and inspection protocols. If you have a specific JIS clause or test you require, we will integrate it into the inspection plan for your order.

Engineering Comparison: Rectangular vs Round-Section Springs for Hand Grippers

| Feature | Rectangular Section | Round Wire Section |

|---|---|---|

| Force density (force per cross-section) | Higher — allows compact designs | Lower — may require larger coils |

| Buckling / lateral stability | Superior — resists side-bending | More susceptible to misalignment |

| Fatigue life (when heat-treated) | Longer when shot-peened & coated | Good, but geometry can concentrate stress |

| Manufacturing tolerance | Tighter tolerance achievable with precision forming | Simple to produce but harder to match exact profile |

| Visual / brand customization | Excellent — flat faces accept coatings and color-coding | Possible — but less surface area for consistent color bands |

Design tips: How to specify rectangular springs for grippers

When you send us drawings or samples, include these key items to accelerate development:

- Target resistance levels (example: 20 kg, 35 kg, 50 kg) and whether you want linear or progressive resistance.

- Maximum allowed assembled length and free length tolerances.

- Preferred material (55CrSi, 50CrVA, or 65Mn) and any special surface requirement (zinc, phosphate + paint, powder coat).

- Color coding plan — specify which force level maps to which color if you want visual differentiation.

- Expected annual volumes — helps us recommend tooling and batch sizes for best unit cost.

Color Options: Build a Clear, Brandable Product Line

Color coding is a simple but powerful marketing and usability mechanism for grippers. We routinely produce rectangular springs in multiple coatings and colors so your assembly line can match resistance levels to a recognizable palette.

Available standard colors:

- Red

- Yellow

- Blue

- Green

- Brown

- Black

Tip for OEMs: match colors to incremental resistance tiers so end-users instantly recognize difficulty levels — this improves UX and reduces support requests about “which one should I buy.”

Real-World Performance: What We Test

We don’t rely on theory only. For every production batch we perform:

- Load-deflection sampling — ensure the force vs. deflection curve matches your spec.

- Cycle fatigue tests — simulate thousands to tens of thousands of cycles depending on the product tier.

- Dimensional and surface inspection — look for burrs, flats, and coating adhesion problems.

- Material traceability — lot numbers for each coil and heat treatment batch.

Typical acceptance criteria we can support

- Load deviation ≤ ±5% for primary resistance points.

- No visible coating flake or peeling after standard adhesion test.

- Fatigue life matched to agreed cycles (we provide test reports).

Why Cixi Dili Spring Co., Ltd. is the Right Partner

We built our capabilities around long-term OEM partnerships. A few facts that matter to procurement and engineering teams:

- Established in 1995 — decades of practical spring design and production experience.

- Full in-house capabilities — R&D, tooling, forming, heat treatment, surface finishing, and batch testing.

- Export-focused — accustomed to meeting international quality expectations with JIS-based processes and traceability.

- Custom development — we accept customer drawings and samples and convert them into production-ready parts with DFM feedback.

- Volume flexibility — from pilot runs to large-scale production, we design the production flow to balance cost and quality.

How we work with OEMs (typical timeline)

- Inquiry & NDA: You share basic specs, target volumes, and optionally a sample.

- Feasibility & Quotation: We provide material options, preliminary tooling notes, lead times, and pricing.

- Prototyping & Testing: We produce samples, provide test reports (load curve, cycle life), and adjust per feedback.

- Pilot Run: Small batch production for assembly-line validation.

- Mass Production & Ongoing Support: Full batches with lot tracking, QA reports, and retooling options as needed.

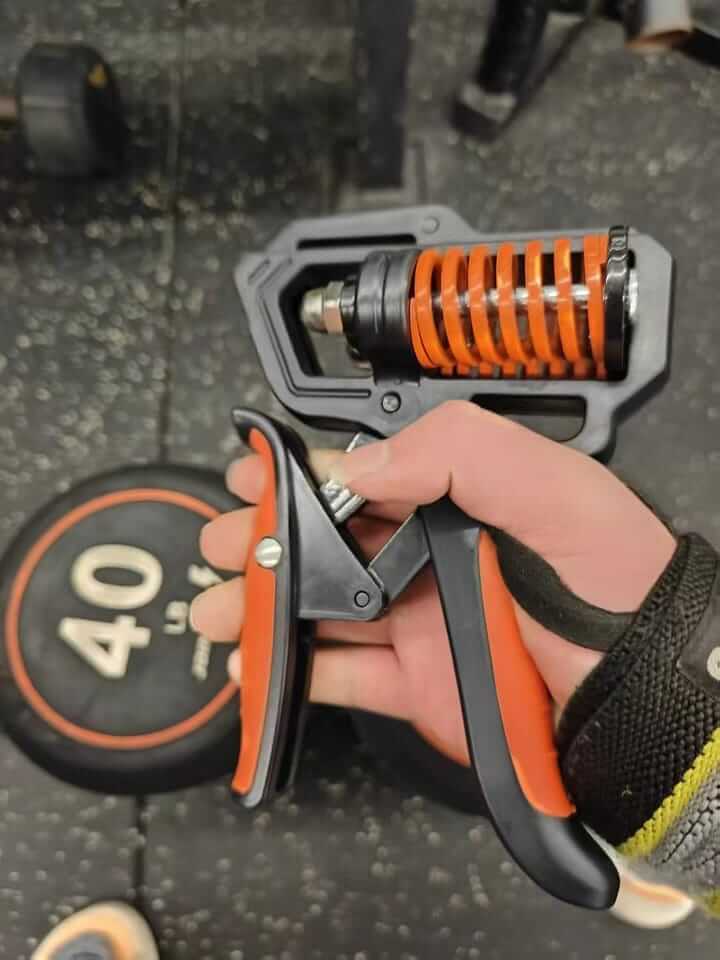

Case Example: Side-by-Side Proof (Use Your Cover Image)

Use the cover image at the top of this article: two different-looking grippers, both using rectangular springs. The visual proof is simple: aesthetic differences don’t change the physics inside. By standardizing on rectangular springs you get consistent behavior across multiple SKUs and different handle designs — that’s a manufacturing advantage.

Messaging you can use in product collateral

“Same premium squeeze across all models — thanks to our rectangular-section springs, color coded for easy selection.”

Frequently Asked Questions (OEM-focused)

Q: Can you match an existing gripper’s resistance exactly?

A: Yes. Provide the assembled dimensions and a sample or a measurement of the target force at a given displacement. We will reverse-engineer the spring or propose a rectangular-section alternative that meets or exceeds the required performance.

Q: Can you supply springs with color-coded coatings for different resistance levels?

A: Absolutely. Standard palette: Red, Yellow, Blue, Green, Brown, Black. We can also accommodate custom color codes for brand-specific requirements or add printed markings on demand.

Q: Do you support RoHS / material compliance documentation?

A: Yes. We can supply material certificates and batch traceability documents as part of the standard QA package for export orders.

Q: What minimum order quantities do you require?

A: MOQ varies by tooling and tolerance requirements; for many rectangular-section designs an MOQ in the low thousands per SKU is typical, but pilot runs for validation are available at lower quantities—contact us for a quote tailored to your needs.

Request Samples & Start Your Next Project

If you’re an OEM ready to upgrade your hand gripper line, the fastest way to decide is to test. We offer engineered samples and small pilot runs so you can evaluate the feel, the fit, and the long-term durability in your own assembly line.

When you contact us, please include: desired resistance levels, preferred material (55CrSi/50CrVA/65Mn), free length limits, and target annual volumes.

About Cixi Dili Spring Co., Ltd.

Cixi Dili Spring Co., Ltd. was founded in 1995 and has been dedicated to high-quality spring manufacturing ever since. We export globally and supply a wide range of springs — from mold springs to torsion and compression springs — with a strong focus on custom solutions. For hand gripper OEMs, we provide engineering feedback, JIS-aligned production practices, and full batch traceability to help you scale confidently.

Key contact

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004

Ready to see the difference? Request a sample today and feel the upgrade. We’ll support you from prototype to production with JIS-informed quality processes, material certificates, and color-coded spring options to align with your brand.

© Cixi Dili Spring Co., Ltd. — Since 1995. All product performance claims depend on final design, material selection, and agreed inspection criteria.