Have you ever wondered what keeps a stamping machine running smoothly through millions of cycles in manufacturing plants from Detroit to Shenzhen, from Stuttgart to São Paulo? What’s the secret behind consistent part quality, minimal downtime, and extended tool life in stamping operations across North America, Europe, and Asia? The answer might surprise you – it’s often a small, green spring that you might overlook at first glance.

ISO 10243 die springs are the unsung heroes of stamping operations worldwide. These precision-engineered components play a critical role in absorbing impact, stabilizing stroke movement, and ensuring fast, precise return under continuous high-load operation. Whether you’re running automotive dies in Mexico, electronics stamping in Taiwan, or appliance manufacturing in Germany, these springs are absolutely essential for any serious stamping operation.

In this comprehensive guide, we’ll explore why ISO 10243 die springs have become the global standard for stamping machines, and what you need to know when selecting them for your tooling – regardless of where in the world your operation is located.

What Makes a Stamping Operation Work Smoothly? (Global Perspective)

Let’s start with the basics. A stamping machine is essentially a high-force press that shapes metal parts through repetitive up-and-down motion. From automotive plants in Tennessee to contract manufacturers in Guangdong, the principle remains the same. Think of it like a giant cookie cutter – but instead of dough, you’re cutting and forming steel, aluminum, or other metals at tremendous force.

But here’s the challenge that manufacturers face whether they’re in Chicago, Tokyo, or Munich: unlike a cookie cutter, a stamping die needs to:

- Return to its exact starting position after every stroke

- Protect itself from the massive shock loads generated during impact

- Maintain precise alignment even after millions of cycles

- Eject or strip the formed part cleanly without damage

This is where die springs come into play. They’re not just “springs” in the general sense – they’re precision-engineered force delivery systems that make all of this possible across industries and continents.

Understanding ISO 10243 Die Springs – The True Global Standard

What Does ISO 10243 Actually Mean for International Manufacturing?

ISO 10243 is an international standard that defines the specifications for rectangular-section die springs used in press tooling worldwide. Originally based on the DIN (German Industrial Standard), this specification has become the truly global benchmark for die spring manufacturing – recognized and used from the United States to China, from Brazil to India.

When you see a green spring in a stamping die – whether that die is in a factory in Ohio, Ontario, Osaka, or Ostrava – chances are it’s an ISO 10243 spring. The standard covers:

- Dimensional tolerances (in metric measurements universally understood globally)

- Load specifications

- Material requirements

- Color coding for easy identification worldwide

- Performance criteria

The beauty of this standardization? An engineer in Germany, China, Mexico, or the United States can specify the same spring using the same part number, and expect identical performance. That’s the power of global standards – and it’s why ISO 10243 has become the preferred specification for multinational manufacturers and their supply chains.

Key Specifications That Matter Across Markets

ISO 10243 springs are categorized by several critical parameters that remain consistent whether you’re ordering from a supplier in Europe, Asia, or the Americas:

Wire Diameter (Dd): This determines the spring’s strength and load capacity. Common sizes range from 5mm to 26mm, with each size carefully calculated to deliver specific force characteristics. These metric dimensions are standard globally, eliminating confusion between imperial and metric systems.

Outer Diameter (Da): The outside dimension of the spring, which determines what size hole it fits into. Standard sizes include 10mm, 13mm, 16mm, 20mm, 25mm, 32mm, 40mm, 50mm, and 63mm – recognized from Detroit to Dongguan.

Free Length (Lo): The uncompressed length of the spring, which dictates the available stroke and installed force.

Load Rating: Identified by colour coding (pale green DIF denotes extremely light loads, green DIL denotes light loads, blue DIM denotes medium loads, red DIH denotes heavy loads, yellow DIB denotes extra-heavy loads, grey DIG denotes extremely heavy loads) — this visual system transcends language barriers.

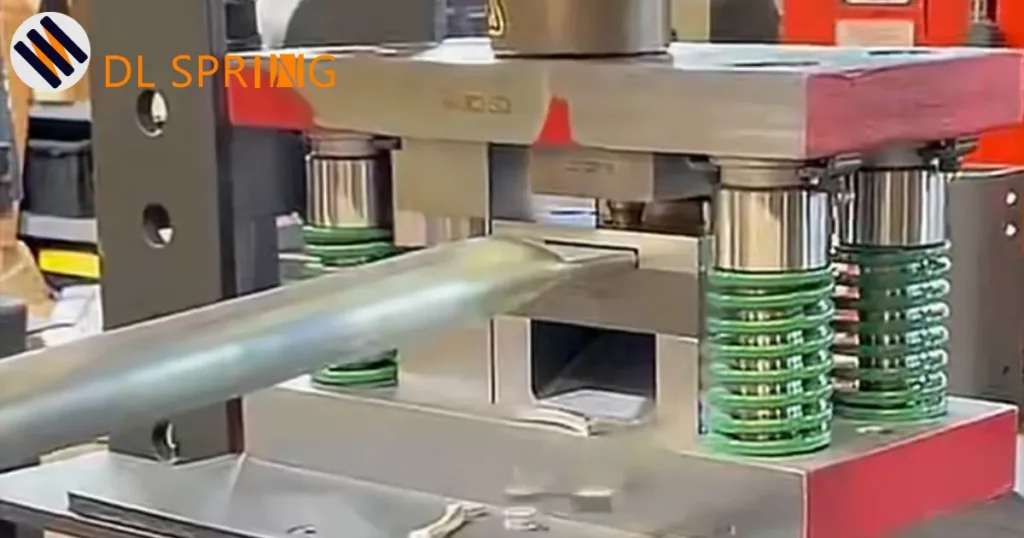

ISO 10243 green die spring featuring precision-ground rectangular wire and consistent coil spacing for reliable performance

As you can see in the image above, ISO 10243 die springs feature a distinctive green coating (indicating light-duty load rating) and precisely wound rectangular-section wire. The uniform coil spacing and ground ends ensure consistent force delivery and stable seating in die pockets. This level of manufacturing precision is what makes ISO 10243 springs so reliable for global stamping operations – whether you order them from a supplier in China, Germany, or the USA.

The Critical Roles of Die Springs in Stamping Machines

Now let’s get to the heart of the matter – what exactly do these springs do in stamping operations around the world? Watch this video to see ISO 10243 die springs in action at a real manufacturing facility:

Absorbing Impact and Shock Loads (Essential in All Manufacturing Regions)

Every time a stamping press cycles – whether it’s in an automotive plant in Michigan, an electronics factory in Shenzhen, or an appliance manufacturer in Poland – tremendous forces are generated in milliseconds. When the punch contacts the material, the impact creates shock waves that travel through the entire die assembly. Without proper spring cushioning, these shock loads would:

- Cause premature wear on precision die components

- Lead to cracking and failure of hardened steel sections

- Create alignment issues that affect part quality

- Reduce overall tool life significantly – increasing costs for manufacturers everywhere

ISO 10243 die springs act as shock absorbers, gradually decelerating the moving components and distributing the impact forces over time rather than allowing instantaneous shock transfer. This is similar to how your car’s suspension protects the chassis from road bumps – except die springs do this millions of times without failure, whether the ambient temperature is the heat of a Texas summer or the cold of a Canadian winter.

Stabilizing Stroke Movement for Global Quality Standards

Consistency is everything in stamping – and it doesn’t matter whether you’re meeting IATF standards for automotive suppliers, ISO quality requirements for European markets, or customer specifications for North American OEMs. If your press stroke varies by even a few hundredths of a millimeter, you’ll see it in your part quality.

Die springs provide the constant force necessary to:

- Keep pressure pads and blank holders at consistent force levels

- Maintain uniform material flow during forming operations

- Prevent wrinkling, tearing, or other forming defects

- Ensure repeatable part dimensions from first piece to millionth piece – critical for global supply chains

The high-quality spring steel and precision manufacturing of ISO 10243 springs means they maintain their force characteristics extremely well over time and across varying environmental conditions. A properly selected spring will deliver virtually the same force on cycle one million as it did on cycle one – whether that’s in a climate-controlled facility in Germany or a non-air-conditioned plant in Southeast Asia.

Ensuring Fast and Precise Return for Maximum Productivity

After the forming operation completes, the die needs to open, and the part needs to be ejected or stripped from the punch. This is where the return stroke becomes critical for maintaining productivity targets – whether you’re running at Western European labor rates or Asian production volumes. ISO 10243 die springs provide:

- Rapid return of stripper plates to their home position

- Forceful ejection of formed parts from die cavities

- Quick reset for the next cycle, maximizing production speed

- Positive separation of die sections to prevent galling and seizing

In high-speed stamping operations running at 200+ strokes per minute – common in electronics manufacturing throughout Asia and automotive component production in Mexico – even a slight delay in return motion can bottleneck your entire production line. Quality die springs ensure the die is ready for the next part the instant the press ram rises, regardless of your production location.

What Happens When You Use the Wrong Spring? (Lessons from Global Manufacturing)

I’ve seen it countless times across manufacturing facilities in multiple countries – someone trying to save a few dollars by using non-standard springs, or selecting the wrong load rating for their application. The results are always the same, whether it’s a shop in Indianapolis, Istanbul, or Incheon:

Premature Spring Failure: Non-ISO springs often use inferior materials or manufacturing processes. They might work for a few thousand cycles, but then you’re changing springs constantly – costing far more in downtime than you saved on the initial purchase. This is especially problematic for companies with global operations who need consistent performance across all facilities.

Inconsistent Part Quality: When spring force varies (because the spring is fatiguing or was wrong to begin with), your forming forces vary. This shows up as dimensional variation, surface finish issues, or even scrap parts – problems that can shut down an entire supply chain when parts don’t meet specification.

Die Damage: Perhaps worst of all, inadequate springs can allow excessive shock loading or misalignment that damages expensive die components. I’ve seen hardened punches crack, die sections shift, and guide pins wear out – all because the wrong springs were installed. When your die was built in one country and is running in another, using non-standard components creates international warranty and support nightmares.

Safety Concerns: In extreme cases, spring failure can cause die malfunctions that create safety hazards for machine operators – a liability issue that crosses all international borders.

The bottom line? Using proper ISO 10243 springs isn’t just about performance – it’s about protecting your investment in tooling and ensuring safe, reliable operation, whether you’re manufacturing in mature markets like North America and Europe or emerging markets throughout Asia, Latin America, and beyond.

How to Select the Right ISO 10243 Die Spring for Your Application

Choosing the right die spring isn’t complicated, but it does require understanding your application requirements. Here’s what you need to consider, regardless of your geographic location:

Load Requirements Analysis

Step 1: Calculate the required force

Start by determining how much force you need from your springs. For stripper applications, this is typically:

- Force to overcome material-to-punch friction

- Force to push the material off the punch during return stroke

- Safety margin (typically 20-30% above calculated minimum)

For cushion applications:

- Force required to control material flow

- Pressure needed for blank holding

- Additional force for overcoming die component friction

Step 2: Determine working stroke

Measure the actual distance your spring will compress during the stamping operation. This is critical because:

- Springs should operate in their optimal force range (typically 20-80% compression)

- Excessive compression leads to solid height issues and premature failure

- Insufficient compression means you’re not using the spring’s capacity efficiently

Step 3: Select spring based on load charts

Using the ISO 10243 specification chart (like the one shown earlier), find springs that deliver your required force at your working compression length. Always check:

- Force at working height (S1)

- Force at 38mm compression (S2) – a standard reference point recognized globally

- Maximum recommended compression

- Travel to solid height

Space Constraints

Die space is always at a premium – whether you’re building compact progressive dies for Asian electronics markets or large transfer dies for North American automotive applications. When selecting springs, you need to balance:

Diameter: Larger diameter springs deliver more force but require more space. Can your die accommodate the necessary pocket size?

Length: Longer springs provide more stroke capability but require deeper pockets. Make sure you have adequate depth in your die shoe.

Quantity vs. Size: Sometimes it’s better to use four smaller springs instead of one large spring – this can improve load distribution and fit constraints better.

Cycle Life Expectations

How long should your die springs last? The honest answer is: it depends on your application – but ISO 10243 springs deliver consistent life expectancy regardless of where they’re manufactured or used.

Factors that reduce spring life:

- Operating springs beyond 80% compression regularly

- Exposure to heat (above 120°C/250°F) – important consideration for plants without climate control

- Contamination with metalworking fluids or debris

- Lateral loading or bending stresses

- Exceeding the spring’s load rating

Pro tip: Plan for scheduled spring replacement based on cycle counts rather than waiting for failure. This prevents unexpected downtime and maintains consistent part quality – critical when you’re shipping parts internationally or supporting just-in-time delivery schedules.

Real-World Applications: Where Die Springs Make the Difference Globally

Let me share some real-world scenarios where ISO 10243 die springs prove their value across different industries and geographic regions:

Automotive Stamping (North America & Mexico): When producing car body panels in NAFTA region facilities, maintaining consistent blank holder pressure is essential for preventing wrinkles and ensuring uniform material draw. Blue-coded medium-duty ISO springs provide the perfect balance of force and travel for these applications. A major automotive supplier with plants in Michigan and Querétaro runs their dies 24/7, and properly selected ISO 10243 springs consistently deliver 5+ million cycles before scheduled replacement – with identical performance on both sides of the border.

Electronics Manufacturing (Asia-Pacific Region): Precision stamping of connector contacts in Taiwan, South Korea, and mainland China requires rapid cycling (often 400+ strokes per minute) with exact return positioning. Green-coded light-duty springs provide quick response with minimal mass, enabling these high-speed operations while maintaining the precision needed for tiny contact dimensions that meet international quality standards.

Appliance Production (Europe & Emerging Markets): Heavy-gauge steel stamping for refrigerator panels or washing machine components in facilities from Germany to Turkey to India demands robust spring support. Red or yellow-coded heavy-duty ISO springs handle the substantial forces involved while absorbing the significant impact loads generated when forming thick materials – performing reliably whether it’s in a state-of-the-art European facility or a developing market production line.

Contract Manufacturing (Global): Job shops serving international customers face unique challenges – dies might be built in one country, shipped to another for production, and serviced by yet another location. The universal standardization of ISO 10243 ensures that springs can be sourced and replaced anywhere in the world without compatibility concerns or performance degradation.

Progressive Die Operations (Worldwide): Multi-station progressive dies often use dozens of die springs performing different functions – stripping, ejection, lifter return, and pressure pad operation. Whether these dies are running in Brazil, Poland, Vietnam, or Canada, the standardization of ISO 10243 ensures consistent performance across all these applications within a single die.

Global Sourcing: Why Choose Cixi Dili Spring for Your ISO 10243 Die Springs?

When it comes to die springs for global manufacturing operations, not all suppliers are created equal. At Cixi Dili Spring Co., Ltd., we’ve been perfecting the art and science of spring manufacturing since 1995 – that’s nearly three decades of expertise serving customers across six continents.

What Sets Us Apart in the Global Marketplace?

✓ Strict ISO 10243 Compliance for International Customers: Every spring we produce meets or exceeds the international standard specifications – whether you’re ordering for a facility in the USA, Germany, Mexico, India, or anywhere else. We don’t cut corners or use “equivalent” dimensions – our springs are true ISO 10243 components that will fit and perform exactly as specified, regardless of where your die was built or where it’s operating.

✓ Comprehensive Quality Certifications Recognized Globally: We maintain both ISO quality management certification and IATF automotive industry certification – credentials that are recognized and respected by manufacturers worldwide. This means our manufacturing processes are continuously audited and improved to deliver consistent, reliable products that meet the strictest international standards.

✓ Export Experience to 40+ Countries: Our springs are used in manufacturing facilities across North America (USA, Canada, Mexico), Europe (Germany, UK, France, Poland, Czech Republic), Asia (Japan, South Korea, Taiwan, Thailand, Vietnam, India), and beyond. We understand the documentation, packaging, and logistics requirements for seamless international shipping.

✓ Full Production Capability Under One Roof: From raw material selection through heat treatment, surface finishing, and final inspection – everything happens in our facility in Cixi, China. This vertical integration gives us complete control over quality at every step, ensuring consistency whether you’re ordering 100 springs or 100,000.

✓ Custom Solutions for Unique Applications: While we stock all standard ISO 10243 sizes, we also offer custom spring manufacturing based on your drawings or samples. Need a special length for a European die builder? A specific load rating for a North American automotive application? Material certification for an aerospace project? We have the engineering support and manufacturing flexibility to deliver exactly what your application requires.

✓ Competitive Pricing with Global Logistics: Manufacturing in China’s advanced industrial region gives us cost advantages we pass on to customers worldwide. We work with reliable international freight forwarders to ensure timely delivery whether you’re in Los Angeles, London, or Lima. Our pricing remains competitive even after international shipping – and our quality matches or exceeds springs manufactured anywhere in the world.

✓ Expert Engineering Support in English: Not sure which spring is right for your application? Our technical team provides engineering support in English for international customers. We can help you analyze your requirements and select the optimal solution, regardless of where in the world your operation is located. We’ve solved spring challenges for thousands of customers across automotive, electronics, appliance, and industrial machinery sectors globally.

✓ Reliable Stock and Fast International Delivery: We maintain substantial inventory of popular ISO 10243 sizes for quick shipment anywhere in the world. For custom or high-volume orders, our efficient production scheduling ensures you get what you need, when you need it – whether you’re in the same time zone or on the opposite side of the planet.

Serving Global Manufacturing from China

As a Chinese manufacturer, we combine the advantages of advanced manufacturing capabilities, competitive pricing, and proven export expertise. We understand that “Made in China” must mean quality and reliability – and that’s exactly what we deliver. Our international customers return to us year after year because our ISO 10243 die springs perform reliably, our quality is consistent, and our service is responsive.

Whether you’re a multinational corporation standardizing components across facilities worldwide, a tier-one automotive supplier with plants in multiple countries, a die shop building tools for international customers, or a local manufacturer competing in global markets – we provide the quality ISO 10243 die springs and international service you need to succeed.

Contact Us – Serving Manufacturers Worldwide

Have questions about die springs for your specific application? Need a quote for international delivery? We’re here to help customers around the world.

Cixi Dili Spring Co., Ltd.

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004

🌐 Serving manufacturers in: USA, Canada, Mexico, UK, Germany, France, Poland, Czech Republic, Japan, South Korea, Taiwan, Thailand, Vietnam, India, Brazil, and 30+ other countries

Conclusion: The Universal Language of Quality Die Springs

ISO 10243 die springs may be small components, but their impact on stamping operations worldwide is anything but minor. From automotive plants in Detroit to electronics factories in Shenzhen, from appliance manufacturers in Milan to contract shops in Monterrey, these precision-engineered springs are critical for:

- ✓ Absorbing destructive impact and shock loads that would otherwise damage expensive tooling

- ✓ Stabilizing stroke movement to ensure consistent part quality that meets international standards

- ✓ Providing fast, precise return for maximum productivity in any market

- ✓ Extending tool life through proper force management – reducing costs globally

- ✓ Ensuring operator safety through reliable, predictable performance across all regions

The key takeaways for global manufacturers:

Always use genuine ISO 10243 springs that meet the international standard – regardless of where you source them or where you use them. Select the right spring based on actual load calculations, not guesswork. And partner with a reliable manufacturer who understands both the technical requirements and the real-world demands of international stamping operations.

At Cixi Dili Spring Co., Ltd., we’ve built our global reputation on delivering exactly that – ISO-compliant die springs that perform reliably through millions of cycles in manufacturing facilities across six continents, backed by expert technical support and responsive international customer service.

Whether you’re building a new die, upgrading an existing tool, or simply need replacement springs you can trust for your global operations – we’re ready to provide the quality components and expertise your operation demands, anywhere in the world.

A small component – but absolutely essential for tool life and production stability worldwide. That’s the ISO 10243 die spring difference, and that’s the Cixi Dili Spring commitment to global manufacturing excellence.

Frequently Asked Questions (FAQ) – International Perspective

1. What’s the difference between ISO 10243 and other die spring standards used internationally?

ISO 10243 is essentially the international version of the DIN (German Industrial) standard, with minor refinements. The dimensions, load ratings, and color codes are compatible, meaning ISO 10243 springs can directly replace DIN springs in existing tooling. Meanwhile, American standards (NAAMS/DADCO) use different sizing systems and color coding – yellow, blue, red, green for increasing loads versus ISO’s green, blue, red, yellow, brown. For global manufacturers with facilities in multiple countries, ISO 10243 has become the preferred specification because it’s recognized across international borders, making sourcing and documentation easier for companies operating in North America, Europe, Asia, and Latin America.

2. Can I source ISO 10243 springs from China for use in North American or European dies?

Absolutely – provided you source from a reputable manufacturer who maintains strict ISO 10243 compliance. The beauty of international standards is that properly manufactured springs perform identically regardless of manufacturing location. At Cixi Dili Spring, we produce ISO 10243 springs that meet the exact same specifications as springs manufactured in Germany, Japan, or the USA – but at more competitive prices due to China’s manufacturing advantages. We export to 40+ countries including USA, Canada, Germany, and UK, with customers who use our springs in dies built anywhere in the world. The key is ensuring your supplier has proper quality certifications (ISO, IATF) and proven export experience. Request material certifications and dimensional inspection reports to verify compliance.

3. How do I know when my die springs need replacement – and can I get replacement springs internationally?

Watch for these warning signs regardless of where your operation is located: (1) Decreased spring height – if a spring has lost more than 5% of its free length, it’s weakening; (2) Visible damage such as cracks, corrosion, or surface pitting; (3) Inconsistent part quality that can’t be explained by other die conditions; (4) Cycle count approaching the expected life for your application. Best practice: keep records of installation dates and cycle counts, and replace springs proactively. For international sourcing, work with suppliers who can provide fast shipping to your location. We regularly ship replacement springs via express courier (DHL, FedEx, UPS) to customers worldwide, with delivery times of 3-7 days to most major manufacturing regions globally.

4. What causes die springs to fail prematurely in different climate conditions?

The most common causes are universal, but climate can play a role: (1) Over-compression – regularly compressing springs beyond their recommended travel damages the material structure; (2) Excessive temperature – heat above 120°C (250°F) weakens spring steel, which can be a concern in non-air-conditioned facilities in tropical climates (Southeast Asia, Latin America, India) or near heat-generating equipment; (3) Humidity and corrosion – while ISO 10243 springs have protective coatings, extremely humid environments (coastal areas, monsoon regions) may require additional corrosion protection; (4) Lateral loading – springs are designed for axial loads only; (5) Using non-standard or low-quality springs – inferior materials drastically reduce life expectancy regardless of location. Quality ISO 10243 springs from certified manufacturers perform reliably in climates from Canadian winters to Southeast Asian tropics.

Ready to Upgrade Your Stamping Dies with Premium ISO 10243 Springs?

Global Manufacturing Demands Global Solutions

Contact Cixi Dili Spring Co., Ltd. today for expert guidance and quality components you can count on, cycle after cycle – delivered anywhere in the world.

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004

Precision springs for precision manufacturing – serving the world since 1995.