This case study shows how handmade spring prototypes used in luxury vehicle window curtains were transformed into reliable, mass-producible components under ISO 9001. Two custom extension springs with unique hooks were engineered to assemble faster, run quieter, and last longer — finished with a basic anti-rust oil and spin-dry process that protects during storage and shipping without staining.

Executive Summary

The client crafts premium window curtains for luxury vehicles in the Mercedes‑Maybach segment and similar high-end conversions. Early prototypes relied on off‑the‑shelf extension springs modified by hand to fit custom rail hardware. That approach worked in small batches but proved inconsistent for scale.

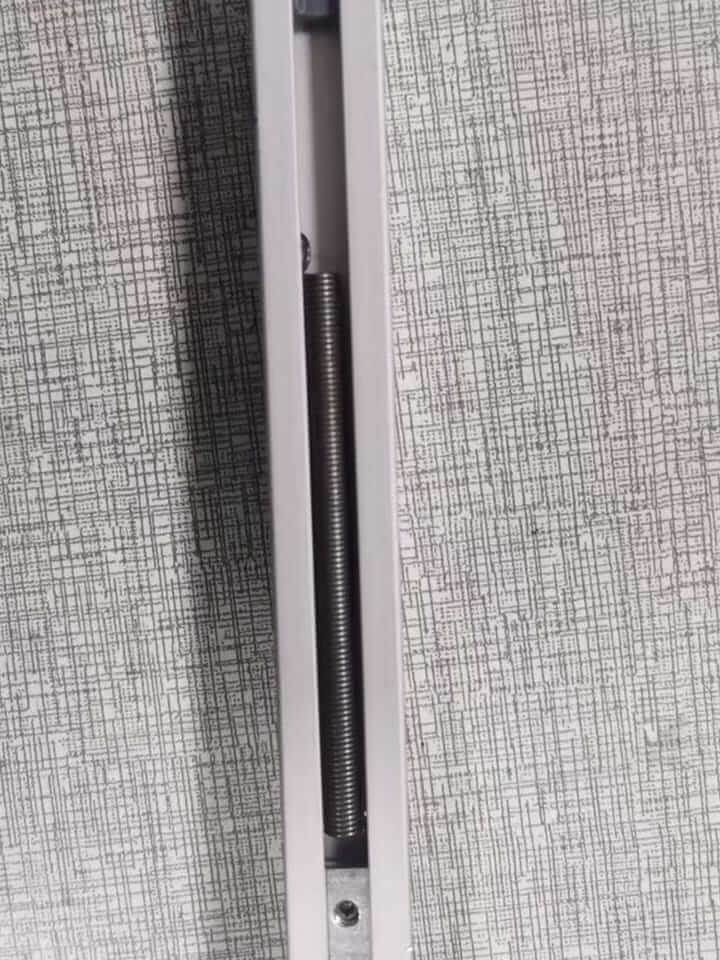

Cixi Dili Spring Co., Ltd. reverse‑engineered the handmade samples and engineered two custom extension springs—one with a half‑turn side hook leaving the opposite end open for assembly, and another with a center hook extended by 10 mm. We prototyped, validated, and mass‑produced under ISO 9001 with clear documentation, repeatable tooling, and packaging that protects hook geometry. A simple, effective surface treatment—light anti‑rust oil followed by a spin‑dry step—provides baseline corrosion protection during storage and transit without sticky residue.

Client Background and Challenge

Luxury interiors demand more than dimensional accuracy: tactile smoothness, silence, and a refined feel across thousands of cycles. Curtain rails are compact and integrated with trim; little space exists for error in coil diameter, free length, or hook geometry. Hand‑modified springs introduced variability in hook shapes and end alignments, which translated into longer assembly time and occasional snagging.

Primary challenges

- Reproduce non‑standard hook forms accurately, including a half‑turn side hook and a 10 mm extended center hook.

- Ensure quiet operation with a consistent force curve across many cycles.

- Prevent hook deformation during shipping and storage.

- Implement a basic yet clean surface protection that would not stain fabric or plastic.

Requirements and Custom Specifications

Spring A (larger)

- Wire diameter: 1.0 mm

- Outer diameter: 15 mm

- Free length: 150 mm

- Ends: one half‑turn side hook; opposite end intentionally left open to speed assembly with the client’s plastic part.

Spring B (smaller)

- Wire diameter: 0.8 mm

- Outer diameter: 6 mm

- Free length: 80 mm

- Ends: one standard hook; the other end is a center hook with a 10 mm outward extension for easier engagement inside the rail.

The client also supplied custom injection‑molded accessories that interface with both springs. These plastic parts control hook orientation, reduce metal‑to‑plastic wear, and contribute to low noise and smooth deployment.

Engineering Discovery: Reverse‑Engineering the Handmade Samples

Once the physical samples arrived, our engineers captured as‑built geometry and mapped the kinematic path inside a rail fixture. We recorded free length, outer and mean diameters, hook angles, bend radii, and the 10 mm overhang of the center hook. We also observed how each hook entered, rotated, and locked, ensuring the extended center hook cleared plastic bosses and fabric folds.

- Coil index: Spring A mean diameter ≈ 14 mm (OD − wire), C ≈ 14; Spring B C ≈ 6.5 — both within healthy ranges for coiling and stress distribution.

- Hook plane alignment: Dedicated fixtures were planned to control hook plane relative to the coil axis—critical for quick assembly in tight rails.

- Tolerance envelope: Tolerances for free length, OD, and hook geometry were negotiated to be tight enough for silent operation yet robust for manufacturing yield.

Material, Surface Finish, and Manufacturability Decisions

Material selection

For interior curtain mechanisms, high‑tensile spring steel (music‑wire grade) offers consistent spring rate and fatigue resistance while keeping cost‑effective. Stainless options were evaluated, but the client prioritized rapid assembly feel and price predictability, making spring steel the right balance when paired with a simple corrosion‑prevention step.

Surface finish: anti‑rust oil + spin‑dry

The agreed finish is a light application of anti‑rust oil followed by a spin‑dry process. This creates a micro‑thin protective film that provides baseline corrosion resistance during storage and normal transportation, without leaving a wet or sticky residue that could attract dust or stain curtain fabrics.

- Purpose: basic corrosion delay under indoor storage and standard shipping humidity.

- Process: controlled application → rotational spin‑dry to remove excess → wipe test to verify clean handling → visual check for uniform sheen.

- Benefits: clean touch, reduced risk of fabric staining, compatibility with the client’s injection‑molded parts, and predictable cost.

- Note: this is not a heavy‑duty anti‑corrosion system; for saline or aggressive environments a different finish (e.g., plating or polymer coat) would be recommended.

Hook forming and stress relief

The half‑turn open hook (Spring A) and the center hook with 10 mm overhang (Spring B) were formed with dedicated tools to control bend radius and plane. Post‑forming stress relief stabilized geometry and minimized residual set, helping preserve hook shape over many cycles.

Coil index

A ≈ 14, B ≈ 6.5

Finish

Anti‑rust oil + spin‑dry

Target

Silent operation & quick assembly

Prototyping and ISO 9001 Process Controls

Though the springs are not from JIS or US standard series, production followed our ISO 9001 quality management system. We mirrored the handmade geometry while making it manufacturable at scale.

- Process plan: coiling parameters per wire size; dedicated hook‑forming fixtures; low‑temperature stress relief to stabilize geometry.

- In‑process checks: free length, OD, hook angles, overhang length; visual for burrs and surface defects; sample‑based spring‑rate checks at specified extensions.

- Traceability: prototype lots labeled by material heat, coiling machine, fixture, operator, and date—records retained per ISO 9001.

- Pilot assembly: with the client’s rail and plastic parts, confirming easy engagement, proper hook orientation, and no fabric snag.

Testing and Validation: Fit, Function, Durability, and Noise

- Fit and function: springs installed in a representative rail mock‑up; both the half‑turn open hook and extended center hook locked securely without twisting the fabric.

- Force feel: progressive pull with controlled return; no “snap” at end‑of‑travel; stable rate across samples.

- Durability: cycle tests checked hook deformation, loss of free length, and spring‑rate drift—all within agreed limits.

- NVH: quiet operation verified; clean, spin‑dried oil film avoided squeaks without contaminating plastics or fabric.

Scaling to Mass Production: QA, Packaging, and Logistics

After sample approval, we scaled with locked parameters and a focus on protecting hook geometry through to the client’s assembly line.

- Repeatable production: prototype tool settings and fixtures were frozen; any change requires internal review and re‑approval.

- Focused inspection: 100% visual checks on hook ends; sample‑based dimensional audits and force tests per lot.

- Packaging: separators and end caps prevent tangling or bending; bundles keep hooks in plane. Labels include part numbers, lot, and quantity for FIFO control.

- Logistics: shipments scheduled to match curtain assembly cadence; documents include measurement reports when requested.

Results and Business Impact

- Faster assembly: the half‑turn open hook and 10 mm center hook cut fiddly maneuvers in tight rails.

- Consistency at scale: controlled tooling and ISO 9001 documentation replaced variable hand‑forming.

- Quiet, premium feel: stable rate and clean surface finish supported smooth, silent operation.

- Lower rejects: fewer hook‑alignment issues reduced rework and scrap.

- Supply assurance: traceable lots, protected packaging, and schedule alignment kept the client’s line flowing.

What This Means for Other Automotive Interior OEMs and Tier Suppliers

For window shades in executive shuttles, luxury vans, and premium sedans, tiny details in spring design drive the in‑cabin experience. The geometry of a hook, the position of an open end, or a 10 mm overhang can be the difference between a silky curtain and a snag‑prone one. If you are migrating from handmade prototypes to steady production, our team can help you lock geometry, validate the force curve, and choose a suitable finish—often the simplest solution (anti‑rust oil + spin‑dry) is the most practical when fabrics and plastics are nearby.

Explore more about our capabilities: Extension Springs, Automotive Springs, and Custom Springs.

Our Standardized Sample‑to‑Ship Workflow

- Requirement intake: share drawings, photos, video, or physical samples. We clarify stroke, preload, rail constraints, and hook orientation.

- Feasibility & DFM: we assess coil index limits, hook plane control, finish compatibility, and packaging needs.

- Quotation & schedule: transparent lead time for prototypes and production; options for pilot lots.

- Prototyping: coiling, forming, stress relief, anti‑rust oil + spin‑dry, inspections, and documentation.

- Validation: fit/function in your rail; adjust tolerances or bend radii if needed.

- Mass production: parameter lock, in‑process checks, protective packaging, and labeling.

- Delivery & follow‑up: we support continuous improvement and track performance by lot.

About Cixi Dili Spring Co., Ltd.

Founded in 1995, Cixi Dili Spring Co., Ltd. designs and manufactures a full range of springs for global customers: mold springs (JIS and US series), torsion springs, compression springs, extension springs, music wire springs, and custom‑shaped springs. We maintain in‑house R&D, production, and sales, and we execute to international standards or customer‑specific drawings as required. For fully custom parts like this case, we rely on a documented, ISO 9001‑certified workflow to ensure stable quality from prototype to shipment.

FAQs

1) Can you match a handmade spring if I don’t have full drawings?

Yes. Send samples and any mating plastic parts or a short video of assembly. We will reverse‑engineer geometry, propose manufacturable hooks, and provide prototypes with measurement reports.

2) Will the anti‑rust oil stain fabric?

The finish is applied lightly and then spin‑dried to remove excess, leaving a microfilm that is dry to the touch. It is designed for clean handling around fabrics and plastics. If your application requires zero oil, we can evaluate alternative finishes.

3) What tests do you perform before mass production?

Dimensional audits, sample‑based spring‑rate checks, surface and burr inspection, pilot assembly in a rail fixture, and durability cycling as agreed. We also verify that hooks retain shape and that operation remains quiet.

4) How do you prevent hook deformation during shipping?

We use separators and end caps, bundle to keep hooks in plane, and mark cartons with handling instructions. Packaging labels include part numbers and lot codes for traceability and FIFO control.

5) Are these springs built to JIS or US standards?

Not in this case. These are fully custom parts built to your specification and controlled under our ISO 9001 system, with drawings and inspection criteria agreed during prototyping.

Start Your Custom Curtain Spring Project

Send us your drawings or physical samples. We’ll prototype, validate, and scale under ISO 9001—keeping your assembly line smooth, silent, and on schedule.

- Email: [email protected]

- WhatsApp: +86 13586942004