In the design of bag making machines, engineers are always seeking more efficient and compact solutions. When traditional rectangular springs cannot meet the demands for ultra-high load or limited space, a powerful alternative emerges: American standard flat wire springs. With their unique flat cross-section design, they demonstrate unparalleled performance advantages in certain critical applications.

This in-depth technical blog will guide you through the specific applications of flat wire springs in bag making machines, analyze their differences and advantages compared to JIS rectangular springs, and help you understand when and why to choose this high-load, high-efficiency solution.

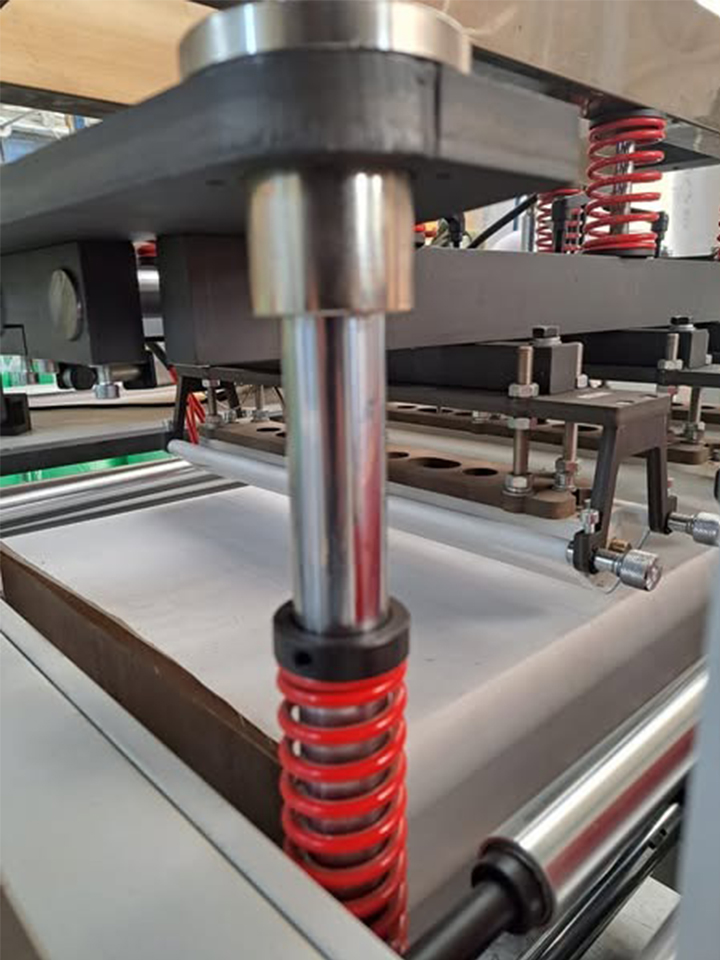

Flat Wire Springs: The Perfect Balance of Force and Space

The cross-section of a flat wire spring is rectangular or trapezoidal, and its greatest technical advantage lies in its ability to provide higher load capacity in a smaller space. Compared to round wire or traditional rectangular springs, flat wire springs distribute stress more evenly upon compression, leading to a higher load-bearing capacity per unit area.

In bag making machines, this characteristic makes them an ideal choice for the following specific applications:

- High-Load Cutting Systems: Some bag making machines need to process multi-layer, heavy composite materials or special bag structures, such as stand-up pouches. This requires the cutting blade to have powerful instantaneous punching force. Flat wire springs can provide this high burst force, ensuring clean and precise cuts.

- Compact Mold Designs: As equipment trends towards smaller, more compact designs, installation space becomes extremely valuable. In cases where mold height is limited, flat wire springs can provide the same or even greater force as larger rectangular springs with a shorter stroke and smaller volume.

- Special Stamping or Forming Mechanisms: In some non-standard bag making machines, there may be mechanisms that require additional punching, indenting, or forming operations on the material. These mechanisms often require extremely high force, and flat wire springs are the ideal choice for providing this stable, powerful force.

Technical Comparison: US Standard Flat Wire vs. JIS Rectangular Springs

While flat wire springs excel in specific scenarios, it’s crucial to understand their differences from JIS rectangular springs when making a choice.

| Characteristic | JIS Rectangular Spring | US Standard Flat Wire Spring |

|---|---|---|

| Standard | Strictly follows JIS B5012, with a unified color-coding system. | Mostly follows manufacturer’s own standards; specifications and color codes are not interchangeable. |

| Load Capacity | Suitable for a variety of loads, from light to heavy. | Offers higher load capacity in the same volume. |

| Fatigue Life | Generally excellent, suitable for high-frequency, high-cycle applications. | May involve a trade-off in fatigue life under heavy loads. |

| Application Scenario | Suitable for most general-purpose bag making machines, providing stable, long-life performance. | Suitable for special bag making machines requiring extreme force and compact space. |

As the table shows, the JIS rectangular spring is a versatile and reliable choice for most bag making machines, while the flat wire spring is a specialized solution born to solve specific technical challenges.

Challenges and Selection Strategy for Flat Wire Springs

Despite their unique advantages, flat wire springs also present some challenges due to their non-universal nature.

- Sourcing and Interchangeability: Due to the lack of a unified standard, specifications for flat wire springs vary between manufacturers. This means that once a choice is made, spare parts must be sourced from the same supplier, increasing supply chain complexity.

- Fatigue Life Trade-off: The design of a flat wire spring prioritizes extreme force, which can impact its fatigue life under high-frequency cycling. Therefore, when selecting, a wise trade-off must be made between **required force and expected lifespan.

How to choose the right flat wire spring?

- Define Needs**: First, accurately assess the maximum force, travel distance, and installation space required by your bag making machine.

- Seek Professional Advice: Partnering with an experienced spring manufacturer is crucial. They can recommend the most suitable flat wire spring based on your technical drawings and application requirements, and provide detailed fatigue life data.

Since 1995, Cixi Dili Spring Co., Ltd. has focused on providing high-quality spring products to global clients. We can not only produce JIS-compliant rectangular springs but also, thanks to our strong R&D capabilities, customize high-quality, high-performance US-standard flat wire springs based on your specific needs. Our team of engineers will work closely with you, starting from your samples or drawings, to provide the most fitting solution, ensuring your machine’s performance is consistently outstanding and reliable.

Our Advantages:

- 29 Years of Focus: Deep experience in the spring industry with rich technical expertise.

- Global Export: Our products are sold worldwide, with quality verified by the market.

- Customization Service: We support personalized production based on client samples or drawings.

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004