Ever wondered what keeps your favorite snack bags perfectly sealed or how shopping bags maintain their consistent quality through mass production? Behind every perfectly formed plastic bag lies a sophisticated mechanical ballet, and at its heart beats an unlikely hero: the JIS standard rectangular die spring. You might think I’m exaggerating, but stick with me – these tiny powerhouses are literally the backbone of modern bag manufacturing.

Understanding the Critical Role of Springs in Modern Bag Making Technology

The Heartbeat of Automated Bag Production

Picture this: a modern automatic bag making machine humming along at 200 bags per minute. That’s over 3 bags every second! At this breakneck pace, every component must perform flawlessly, and here’s where our rectangular springs come into play. They’re not just sitting there – they’re compressing and releasing thousands of times per hour, ensuring each seal is perfect and every cut is clean.

The bag making process might seem simple from the outside, but it’s actually a complex orchestration of multiple systems:

- Film Unwinding and Tension Control

- Heat Sealing Operations

- Cutting and Perforation

- Stacking and Counting

Among these stages, heat sealing and cutting are where rectangular springs truly shine. Without them, you’d have bags with weak seals that burst open, jagged edges that look unprofessional, or worse – a completely jammed production line costing thousands in downtime. At Cixi Dili Spring Co., Ltd., we’ve seen firsthand how the right spring selection can make or break a production line’s efficiency.

The Physics Behind Perfect Sealing

Let’s get a bit technical here (don’t worry, I’ll keep it digestible). When a heat sealing bar comes down on plastic film, it needs to apply uniform pressure across the entire sealing width. Too much pressure? You’ll burn through the material. Too little? The seal won’t hold. This is where the spring’s job becomes critical.

The rectangular spring acts as a pressure regulator and shock absorber. It ensures that even if there are minor variations in film thickness or if the machine components aren’t perfectly aligned, the sealing pressure remains consistent. Think of it like the suspension in your car – it smooths out the bumps to give you a comfortable ride. Similarly, these springs smooth out manufacturing inconsistencies to give you perfect bags every time.

Why JIS Standard Rectangular Springs Dominate the Industry

The Japanese Engineering Excellence

You’ve probably heard about Japanese precision in manufacturing – well, JIS (Japanese Industrial Standards) springs are a perfect example of this philosophy in action. The JIS B5012 standard didn’t just happen overnight; it’s the result of decades of refinement in the demanding Japanese manufacturing sector. Our JIS die spring collection represents the pinnacle of this engineering excellence.

But what makes these springs so special compared to, say, regular compression springs or other international standards?

1. Superior Load Distribution Through Rectangular Cross-Section

Traditional round wire springs have a circular cross-section, which creates stress concentration points during compression. Imagine squeezing a rubber ball – the pressure isn’t evenly distributed. Now imagine squeezing a rectangular block – the force spreads more evenly across the surface.

This rectangular design means:

- 40% better stress distribution compared to round wire springs

- Reduced risk of stress fractures at high cycle counts

- More predictable compression behavior over the spring’s lifetime

2. The Genius of Color-Coded Load Classification

Here’s something that makes engineers smile: JIS springs use a universal color-coding system that transcends language barriers. Whether you’re in Tokyo, Detroit, or Munich, everyone knows:

| Color | Load Rating | Typical Application in Bag Making |

|---|---|---|

| Yellow | Extra Light Load | Thin film guide mechanisms, sensor actuators |

| Blue | Light Load | Standard plastic bag sealing (20-40 microns) |

| Red | Medium Load | Heavy-duty bag sealing, multi-layer films |

| Green | Heavy Load | Cutting operations, thick material processing |

| Brown | Extra Heavy Load | Industrial sack production, woven bag cutting |

This standardization is a game-changer for maintenance teams. No more measuring spring rates or consulting complicated charts – just match the color and you’re good to go! Learn more about this color-coding system and other technical specifications in our die springs blog section.

3. Precision Manufacturing Tolerances

JIS standards demand incredibly tight tolerances:

- Spring rate variation: ±5% maximum

- Perpendicularity: Within 1.5 degrees

- Free length tolerance: ±1% of nominal length

- Surface finish: No visible cracks under 10x magnification

These aren’t just numbers on paper – they translate directly to machine performance. A spring that’s even slightly out of spec can cause uneven sealing, premature wear on other components, or catastrophic failure during production.

Real-World Applications: Springs in Action

Heat Sealing Systems: The Perfect Marriage of Heat and Pressure

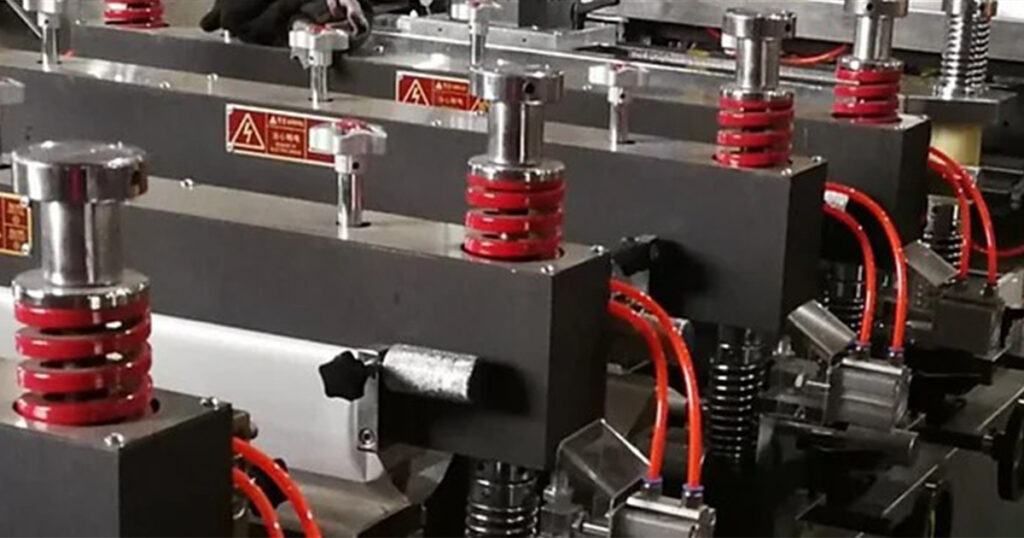

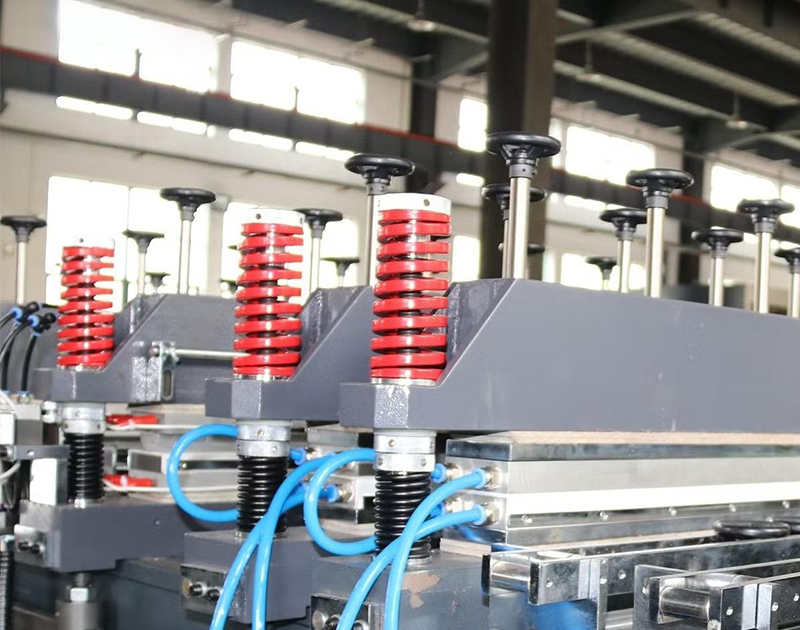

In a typical bag making machine, the heat sealing system uses anywhere from 4 to 20 rectangular springs, depending on the sealing bar length. These springs are strategically positioned to:

- Provide initial contact pressure (typically 2-5 kg/cm²)

- Maintain consistent force during the dwell time (0.2-0.8 seconds)

- Enable quick release for the next cycle

Let me paint you a picture: imagine you’re making grocery bags at 150 bags per minute. Each sealing cycle lasts roughly 0.4 seconds. During this brief moment, the springs must:

- Compress smoothly to accommodate film thickness variations

- Maintain steady pressure while the heat does its work

- Release quickly without bouncing or vibration

- Reset perfectly for the next bag

That’s 9,000 perfect cycles per hour, 72,000 per shift, potentially millions per month. Only high-quality JIS springs can handle this punishment day after day.

Cutting Mechanisms: Precision Under Pressure

The cutting system presents different challenges. Here, springs must provide:

- Explosive release force for clean cuts

- Precise depth control to avoid cutting too deep

- Vibration dampening to prevent blade chatter

Think about cutting a piece of paper with scissors versus a guillotine paper cutter. The guillotine gives you that satisfying, clean cut because of the rapid, controlled force. That’s exactly what properly specified rectangular springs provide in bag cutting operations.

Selecting the Right Springs for Your Bag Making Machine

Understanding Your Machine’s Requirements

Choosing springs isn’t like picking apples at the grocery store – it requires careful consideration of multiple factors:

1. Operating Speed and Cycle Rate

- Low speed (< 50 bags/min): Standard load springs often sufficient

- Medium speed (50-150 bags/min): Consider medium to heavy load ratings

- High speed (> 150 bags/min): Heavy or extra-heavy load essential

2. Material Characteristics

- Thin films (< 30 microns): Light load springs prevent film damage

- Standard thickness (30-80 microns): Medium load provides optimal sealing

- Heavy materials (> 80 microns or multi-layer): Heavy load ensures complete fusion

3. Environmental Conditions

- Standard factory: Regular chrome silicon steel springs

- High temperature: Special heat-resistant alloys required

- Corrosive environment: Stainless steel or coated options

For personalized spring selection assistance, don’t hesitate to contact our technical team – we’re always happy to help you find the perfect match for your specific application.

The Hidden Costs of Cheap Springs

I can’t stress this enough: cutting corners on springs is like putting cheap tires on a Ferrari. You might save a few dollars upfront, but the hidden costs will eat you alive:

- Increased downtime: Failed springs mean stopped production

- Quality issues: Weak seals lead to customer complaints and returns

- Cascading damage: A broken spring can damage molds, heating elements, and frames

- Labor costs: Frequent replacements mean more maintenance hours

When you calculate the true cost of ownership, quality JIS springs from reputable manufacturers like Cixi Dili Spring Co., Ltd. actually save money in the long run.

Maintenance Best Practices: Maximizing Spring Lifespan

Regular Inspection Protocols

Don’t wait for springs to fail – implement a proactive inspection schedule:

Daily Visual Checks:

- Look for obvious deformation or color fading

- Check for unusual machine sounds during operation

- Monitor seal quality for consistency

Weekly Measurements:

- Verify free length hasn’t decreased more than 2%

- Check spring alignment in mounting holes

- Ensure no debris accumulation around springs

Monthly Comprehensive Review:

- Remove and inspect springs under magnification

- Test spring rate if equipment available

- Document findings for trend analysis

When to Replace: The Critical Indicators

Springs don’t usually fail catastrophically – they give warning signs:

- Free length reduction > 5%: Spring has taken a permanent set

- Visible cracks or corrosion: Structural integrity compromised

- Uneven compression: One end compresses more than the other

- Color significantly faded: May indicate overheating or chemical exposure

- Machine requires frequent adjustments: Springs no longer providing consistent force

Storage and Handling Tips

Proper storage extends spring life before installation:

- Store in original packaging to prevent damage

- Keep in dry, temperature-controlled environment

- Avoid stacking heavy items on spring boxes

- Use FIFO (First In, First Out) inventory rotation

- Handle with clean gloves to prevent corrosion

Industry Trends and Practical Improvements in Spring Applications

Current Manufacturing Innovations

The spring manufacturing industry continues to evolve, not through science fiction concepts, but through practical improvements that directly benefit bag making operations:

Enhanced Material Processing: Recent advances in steel treatment have produced springs with 30% better fatigue resistance without increasing costs significantly. These improvements come from better understanding of heat treatment processes and micro-alloying techniques that have been perfected over the past decade.

Improved Surface Treatments: New coating technologies now offer:

- Better corrosion resistance in humid environments

- Reduced friction for smoother operation

- Extended service life in high-temperature applications

These aren’t futuristic promises – they’re available today in our premium JIS spring range.

Quality Control Advancements: Modern testing equipment allows manufacturers to verify spring characteristics more accurately than ever before. Every batch can now be tested for:

- Exact load ratings at multiple compression points

- Fatigue life prediction based on accelerated testing

- Dimensional accuracy to micron-level precision

What This Means for Your Operation

These incremental improvements translate to real benefits:

- Longer intervals between spring replacements

- More consistent product quality

- Reduced total maintenance costs

- Better predictability in production planning

The key is working with manufacturers who invest in these technologies and can deliver their benefits to your production floor.

Why Choose Cixi Dili Spring Co., Ltd. for Your Spring Needs?

Since 1995, we’ve been more than just spring manufacturers – we’re problem solvers for the packaging industry. Our JIS rectangular springs aren’t just products; they’re the result of nearly three decades of continuous improvement and customer feedback.

What sets us apart:

1. Uncompromising Quality Standards

Every spring leaving our facility has passed through:

- Raw material certification (mill certificates for all steel)

- In-process quality checks at 5 production stages

- Final inspection including load testing and dimensional verification

- Batch traceability for complete quality assurance

2. Customization Capabilities

While we excel at standard JIS springs, we understand that sometimes you need something special:

- Custom load rates for unique applications

- Special coatings for harsh environments

- Modified dimensions for retrofit applications

- Prototype development for new machine designs

Browse our complete product range to see standard options, or reach out to us for custom solutions.

3. Global Supply Chain Excellence

With customers across 6 continents, we’ve mastered the art of:

- Just-in-time delivery to minimize your inventory costs

- Emergency shipments for unexpected breakdowns

- Technical support in multiple time zones

- Competitive pricing through efficient manufacturing

4. Technical Partnership Approach

We don’t just sell springs – we partner with you to:

- Analyze your specific application requirements

- Recommend optimal spring specifications

- Provide installation and maintenance guidance

- Support your continuous improvement initiatives

For more technical insights and industry updates, visit our die springs blog where we regularly share maintenance tips, case studies, and best practices.

Conclusion: The Small Component with Big Impact

Next time you see a perfectly sealed plastic bag, remember the unsung hero working behind the scenes. JIS rectangular springs might be small, but their impact on bag making efficiency and quality is enormous. They’re the difference between a production line that runs smoothly for years and one plagued by constant issues.

Choosing the right springs isn’t just about meeting specifications – it’s about ensuring your entire operation runs at peak efficiency. With proper selection, installation, and maintenance, quality JIS springs will serve as the reliable heartbeat of your bag making machines for millions of cycles.

Don’t let something as critical as springs be an afterthought in your operation. Partner with experienced manufacturers who understand not just springs, but your entire application. At Cixi Dili Spring Co., Ltd., we’ve spent 29 years perfecting the art and science of spring manufacturing, and we’re ready to help your bag making operation reach new levels of efficiency and reliability.

Frequently Asked Questions (FAQ)

Q1: How often should I replace the springs in my bag making machine?

A: There’s no one-size-fits-all answer, as replacement frequency depends on several factors including operating speed, material type, and environmental conditions. However, as a general guideline:

- High-speed operations (>150 bags/min): Every 6-12 months

- Medium-speed operations (50-150 bags/min): Every 12-18 months

- Low-speed operations (<50 bags/min): Every 18-24 months

Always prioritize actual spring condition over time-based replacement. Regular inspections will help you identify when springs are approaching their service limit. Check our technical blog for detailed inspection guides.

Q2: Can I mix different brands of JIS springs in the same machine?

A: While JIS standards ensure dimensional compatibility, we recommend using springs from the same manufacturer when possible. Different manufacturers may use slightly different steel alloys or manufacturing processes, leading to minor variations in performance. Mixing brands can result in uneven wear patterns or inconsistent sealing pressure. If you must mix brands, ensure they have identical specifications and monitor performance closely during the first few production runs.

Q3: What’s the difference between JIS, DIN, and ISO standard springs for bag making machines?

A: While all three standards produce quality springs, there are key differences:

- JIS (Japanese): Emphasizes fatigue resistance and uses color coding, ideal for high-cycle applications

- DIN (German): Focuses on precise load ratings and material specifications, excellent for heavy-duty use

- ISO (International): Provides broader compatibility but may have looser tolerances than JIS or DIN

For bag making machines, JIS springs are often preferred due to their superior fatigue life and convenient color-coding system. However, DIN springs can be excellent alternatives for heavy-duty applications. View our full JIS spring catalog for detailed specifications.

Q4: How can I tell if my springs are causing seal quality issues?

A: Springs-related seal problems typically show specific patterns:

- Weak seals in specific spots: Indicates individual spring failure

- Gradually weakening seals over time: Suggests springs are losing their load capacity

- Inconsistent seal strength: May mean springs have different compression rates

- Seal burn-through: Could indicate springs are over-compressed

To diagnose, check the free length of all springs and compare to specifications. Also, observe the sealing bar during operation – it should compress evenly across its entire length. For expert diagnosis, contact our technical support team.

Q5: Is it worth investing in premium springs versus standard ones?

A: Absolutely! Let’s do the math: Premium springs might cost 30-50% more than standard ones, but they typically last 2-3 times longer and maintain consistent performance throughout their lifespan.

Consider this scenario:

- Standard springs: $20 each, replaced every 6 months, plus 2 hours downtime per change

- Premium springs: $30 each, replaced every 18 months, plus 2 hours downtime per change

Over 3 years, you’d save not just on spring costs but significantly on labor and lost production time. Plus, premium springs reduce quality issues, customer complaints, and secondary damage to other machine components.

Ready to upgrade your bag making machine’s performance with premium JIS rectangular springs?

Visit Cixi Dili Spring Co., Ltd. or contact us directly for a consultation:

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004

Let’s work together to keep your production lines running at peak efficiency!