Spring End Face Grinding — The Critical Process That Determines Spring Performance

Have you ever encountered this problem: The spring material and design clearly meet requirements, but after installation, you experience uneven force distribution, abnormal noise, or even premature failure? The issue likely lies in an often-overlooked step — end face grinding.

Among the many processes in spring manufacturing, end face grinding, though the final “finishing” step, directly affects whether the spring can perform properly. Imagine if both ends of a compression spring are uneven — like a table with four legs of different lengths, no matter how good the material is, it cannot bear loads stably. This is why professional spring manufacturers invest significant effort in end face grinding.

This article will take you deep into the complete process of spring end face grinding — from technical standards to equipment selection, from process principles to quality control. Whether you’re an engineer, procurement specialist, or customer wanting to understand spring manufacturing details, this article will provide practical reference.

Why Is Spring End Face Grinding Indispensable?

Perpendicularity Determines Load-Bearing Capacity

When compression springs work, they need to uniformly transfer force between the end faces and mounting base. If the end face is not perpendicular to the spring axis, it causes stress concentration — some coils bear loads they shouldn’t, while others “slack off.” This not only reduces the spring’s effective load-bearing capacity but also accelerates fatigue damage.

Contact Precision Affects Service Life

Rough or uneven end faces reduce contact area and increase unit pressure. It’s like walking on soft ground in high heels — the heels sink deeply. The same happens with spring end faces; localized excessive wear rapidly shortens service life.

Host Machine or Component Characteristic Requirements

In many precision applications (such as die springs or fuel injector pressure-regulating springs), host machines have strict requirements for spring parallelism and stability. End face grinding is the key process to ensure these characteristics.

End Face Grinding Technical Standards and Quality Requirements

According to international standards and engineering practice, helical compression spring end face grinding must meet the following requirements:

Ground Length Standard

Ground portion not less than 3/4 of circumference — meaning at least 270° contact arc. Why 3/4 and not complete? Because complete grinding increases unnecessary costs, while 3/4 contact surface is sufficient to ensure stability and perpendicularity.

End Thickness Requirements

End thickness not less than 1/8 of material diameter (1/4 is ideal). This standard ensures end face flatness while avoiding material strength reduction from excessive grinding. Weak ends easily undergo plastic deformation under repeated loading.

Surface Roughness Control

Ra≤12.5μm — this value ensures good contact characteristics; not so rough as to cause wear, nor needing mirror-like precision (which would significantly increase costs).

These standards aren’t arbitrarily set but represent the optimal balance point derived from years of engineering practice.

End Face Grinding Machine Types and Selection Strategy

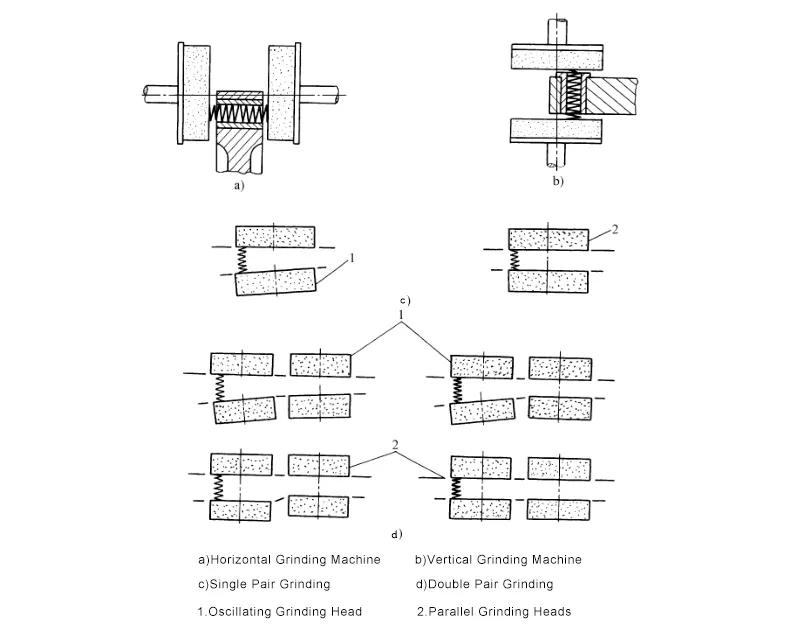

Spring end face grinding machines mainly fall into two types: horizontal grinding machines and vertical grinding machines. Which equipment to choose depends on your production volume, spring specifications, and automation requirements.

Horizontal Grinding Machines: Suitable for Large-Batch Production

Horizontal grinding machines position springs horizontally with grinding wheels simultaneously grinding both ends from the sides. This structure offers good stability, suitable for large-diameter, large-batch spring production. For example, automotive suspension springs and other thicker springs typically use horizontal grinding machines.

Vertical Grinding Machines: Flexible and Efficient

Vertical grinding machines position springs vertically with grinding wheels grinding from top and bottom ends. This design saves floor space with more convenient loading/unloading, especially suitable for medium-small batches with multiple specification changes.

Automation Level Selection

Based on volume and cost considerations, grinding equipment can be divided into three operation modes:

- Manual Grinding: Using ordinary grinding wheels with fixtures and auxiliary tools, equipment is simple but labor-intensive, suitable for diverse varieties with small batches.

- Semi-Automatic Grinding: Partial process automation, operators mainly handle loading/unloading and parameter adjustment, balancing efficiency and flexibility.

- Fully Automatic Grinding: Such as CNC double-disc grinding machines (M7745-9KS type) or computer grinding machines (φ0.5~φ12mm), enabling automatic feeding, grinding, and inspection, suitable for large-batch standardized production.

Dust Collection System Importance

The grinding process generates substantial metal dust, requiring dust collection systems:

- Water Spray Dust Collection: Uses water flow to carry away dust, effective but requires wastewater treatment

- Vacuum Dust Collection: Uses negative pressure to extract dust, more environmentally friendly but slightly higher equipment cost

In-Depth Analysis of Grinding Process Principles

Opposing Grinding Head Method — Mainstream Process

According to grinding machine configuration, opposing grinding head grinding can be divided into two methods:

Single Pair Grinding Head Grinding

Two grinding wheel spindles at 0°~3° angle, two grinding wheels forming a trumpet mouth. This method suits rough grinding spring end faces with higher efficiency but slightly lower precision.

Double Pair Grinding Head Grinding

One pair of grinding wheels for rough grinding, one pair for precision grinding, two processes completed synchronously. This method significantly improves production efficiency and quality stability, the preferred solution for modern production.

Grinding Strategies for Different Wire Diameters

Steel wire diameter ≥3mm: Can be divided into rough grinding and precision grinding processes — rapid flattening first, then surface refinement.

Steel wire diameter <3mm: Finer material with stricter perpendicularity and free height requirements (such as fuel injector pressure-regulating springs), typically requiring two or three grinding passes, progressively correcting precision.

Production Process Video Demonstration

To give you a more intuitive understanding of the grinding process, we’ve created actual production footage:

The video shows the complete process from spring loading, positioning, synchronous double-pair grinding head grinding to unloading inspection. You can clearly see how grinding wheels precisely contact spring end faces and how automated equipment improves production efficiency.

Key Quality Control Points in Actual Production

In actual production, obtaining high-quality end face grinding results requires attention to the following key points:

Material Pretreatment Importance

Before grinding, check spring material hardness, roughness, and binder to ensure material suits grinding wheel characteristics. Material too hard accelerates grinding wheel wear; too soft makes ideal surface quality difficult.

Grinding Speed and Temperature Control

This is the most easily overlooked issue. If grinding speed is too fast or grinding wheel selection improper, frictional heat can cause:

- Overburn: End face turns blue or discolored, material hardness decreases

- Cracks: Temperature sudden changes cause surface cracking

- Residual Stress: Affects spring fatigue life

Therefore, when grinding volume is large or rotation speed is high, must use coolant or cooling airflow. Generally, rough grinding can be done before quenching, precision grinding after quenching.

Sleeve Fit Precision Management

To ensure ground spring perpendicularity meets requirements, sleeve inner hole and length must properly fit the spring:

- If clearance is too small, spring cannot enter sleeve

- If clearance is too large or sleeve too long, spring tilts inside sleeve, reducing grinding precision

Empirical data: Sleeve inner diameter should be 0.1~0.2mm larger than spring outer diameter. Short spring sleeve height is 1~3mm lower than spring; long spring sleeve height is 2~5mm lower than spring.

Helix Angle Maintenance Technology

When grinding springs on grinding machines, to ensure perpendicularity, helix angle must be uniform and consistent. This requires controlling helix angle during grinding, ensuring control within the sleeve. When perpendicularity requirements are high, can use universal angle ruler or special template to measure helix angle.

Annealing and Grinding Sequence

To avoid end face opening, grinding process should be done after annealing. For springs requiring coiling annealing, rough grinding can be done before quenching, precision grinding after quenching. This both improves efficiency and ensures quality.

Inner Hole Chamfering Treatment

After spring end face grinding, inner holes produce burrs. To avoid scratching or affecting assembly, need to perform inner hole chamfering (deburring) treatment. Common tools include:

- Special conical grinding wheels

- Cone carbide conical cutting tools

- Automatic inner hole chamfering machines (higher efficiency)

Equipment Maintenance and Care

Regular grinding wheel dressing and equipment maintenance adjustment is the foundation for ensuring grinding quality. Grinding wheels become dull or deformed with prolonged use and must be dressed promptly.

Common Quality Issue Troubleshooting and Solutions

Even with strict standard operations, quality issues may still occur in production. Below are common defects and solutions:

| Quality Issue | Possible Causes | Solutions |

|---|---|---|

| Uneven end face | Improper sleeve fit, grinding wheel wear | Check sleeve clearance, dress grinding wheel promptly |

| Helix angle deviation | Unsuitable sleeve height, inaccurate positioning | Adjust sleeve dimensions, use special template inspection |

| End face overburn | Grinding speed too fast, no cooling | Reduce feed rate, add coolant |

| End face cracking | Material quenching stress large, drastic temperature changes | Adjust annealing sequence, control grinding temperature |

| Surface roughness exceeds standard | Inappropriate grinding wheel grit, feed too fast | Select fine-grit grinding wheel, adopt precision grinding process |

Cixi Dili Spring’s End Face Grinding Solutions

As a professional spring manufacturer established in 1995, Cixi Dili Spring Co., Ltd. has accumulated nearly 30 years of experience in end face grinding processes.

Our Equipment and Process Capabilities

We are equipped with fully automatic CNC spring grinding machines and computer-controlled grinding machines, capable of processing end face grinding for various springs from φ0.5 to φ12mm. Whether die springs, compression springs, extension springs, or custom springs, we can provide high-precision end face processing services.

Strict Quality Control System

We strictly implement international standards and conduct customized production according to customers’ special requirements:

- End face parallelism controllable within 0.05mm

- Surface roughness stable at Ra≤12.5μm

- Equipped with professional testing equipment, 100% factory inspection

Complete Support from Sample to Mass Production

Whether you provide samples or drawings, our R&D team can respond quickly, providing one-stop service from design optimization to mass production. Our products are exported globally, serving automotive, die, machinery, electronics, and other industries.

If you have spring end face grinding needs, welcome to contact us:

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004

Summary and Action Recommendations

Spring end face grinding seems simple but is actually a key process ensuring spring performance. From equipment selection to process parameters, from material pretreatment to quality inspection, every link directly affects final product quality.

Core Points Review:

- ✅ End face grinding directly affects spring perpendicularity, load-bearing capacity, and service life

- ✅ Technical standards: Ground length ≥3/4 circumference, end thickness ≥1/8 material diameter, Ra≤12.5μm

- ✅ Equipment selection should comprehensively consider volume, specifications, and automation requirements

- ✅ Opposing grinding head grinding is mainstream process, double-pair grinding heads more efficient

- ✅ Temperature control, sleeve fit, helix angle maintenance are key to quality control

Action Recommendations:

- If you’re an engineer, recommend considering end face grinding processability at design stage to avoid later rework

- If you’re a procurement specialist, when selecting suppliers be sure to inspect their grinding equipment and quality control capabilities

- If you need customized springs, welcome to communicate specific requirements with us — we’ll provide professional technical support

Springs may be small, but craftsmanship is meticulous. Choose professional partners to make your products more reliable.

FAQ – Frequently Asked Questions

Q1: Do all springs need end face grinding?

Not necessarily. Mainly helical compression springs need end face grinding to ensure both ends are parallel and perpendicular to the axis. Extension springs, since they mainly bear tensile force during work, have lower end face flatness requirements. Torsion springs typically don’t require end face grinding. Additionally, for some non-critical applications (such as simple buffering springs), grinding processes can be omitted to reduce costs.

Q2: Is there a significant quality difference between manual and automatic grinding?

From surface roughness and ground length perspectives, the difference isn’t large — experienced technicians can achieve standards with manual grinding. However, in perpendicularity consistency, production efficiency, and batch stability, automatic equipment has clear advantages. Automatic grinding machines can precisely control grinding parameters for each spring, while manual operation inevitably has fluctuations. Therefore, large-batch production strongly recommends using automatic or semi-automatic equipment.

Q3: How to determine if spring end face grinding quality is qualified?

Can be tested through the following methods:

- Visual inspection: End face should have no obvious burn marks, cracks, or pits

- Flat plate test: Place spring on flat plate, observe if contact area reaches 3/4 circumference

- Parallelism measurement: Use parallelism detector or vernier caliper to measure parallelism deviation between two end faces

- Surface roughness meter: Measure if Ra value ≤12.5μm

- Functional test: Test spring stability and load-bearing uniformity under actual working conditions

Q4: Why do small diameter springs (such as φ0.5mm) need multiple grinding passes?

Small diameter springs have fine material and poor rigidity, easily producing bending deformation during grinding. If single-pass grinding removal is excessive, springs will produce skewing due to uneven force. Using two or three grinding passes, removing small amounts of material each time, can progressively correct end faces, ultimately achieving higher perpendicularity and parallelism. It’s like sculpting art — rough blank rapid forming, refinement slow polishing.

Q5: Does spring end face grinding affect spring elasticity?

Under normal circumstances, no. End face grinding only removes small amounts of material from both ends to obtain flat surfaces, not changing spring effective coil count and free height (or slightly reducing free height). However, if grinding is excessive (end thickness less than 1/8 material diameter) or grinding temperature too high causing annealing, it may affect end material hardness and elasticity. This is why we emphasize strict control of grinding amount and temperature.