The frustration is universal among 3D printing enthusiasts: the constant need for bed re-leveling. It is a tedious ritual that often seems to defy resolution, leading to failed prints, warped corners, and poor first-layer adhesion. Many users find themselves questioning the foundational stability of their prints. Is your critical first layer truly resting on a stable platform, or is it hovering precariously on a wobbly base that yields to every vibration and thermal cycle?

The instability often originates with one of the most overlooked components: the bed leveling springs. The solution is not a software tweak but an engineered, industrial-grade mechanical upgrade, borrowed directly from the world of high-precision tool and die manufacturing: the die spring. By replacing flimsy, low-grade stock components with springs engineered for millions of cycles under high load, enthusiasts can achieve a level of stability previously reserved for professional industrial machinery. This commitment to engineered reliability is central to the operations of Cixi Dili Spring Co., Ltd., which has been manufacturing the precision springs that stabilize industrial processes across the globe since 1995. This report details the engineering principles behind the yellow die spring upgrade and why it is the definitive solution for long-term bed leveling stability.

The Engineering Imperative: Why Your Stock Springs Are Undermining Your Prints

Achieving high-quality 3D prints requires a perfectly stable and consistent relationship between the extruder nozzle and the print surface. When prints fail or require constant attention, the source is often the mechanical weakness of the stock components.

Identifying the Weak Link: The Flaws of Standard 3D Printer Compression Springs

The springs included with most desktop 3D printers are typically generic, low-quality compression springs made from standard, round-wire steel. While inexpensive to manufacture, they are prone to several critical engineering flaws that make them unsuitable for the demands of a heated, high-vibration environment.

The primary issue is the low spring rate—known as the k value in Hooke’s Law (F = -kx). A low spring rate means the springs are too compliant; they compress too easily under minor fluctuations in load or minor shifts in the leveling knob position. This compliance is a direct path to the rapid loss of level. Even more concerning is the material composition. Low-grade spring steel is highly susceptible to stress relaxation and fatigue when exposed to the repeated thermal cycles of a heated print bed, which can range from room temperature up to 110 degrees Celsius. Over time, under heat and load, the material loses its set and original force. This progressive weakening demands ever-increasing micro-adjustments from the user, eventually leading to a scenario where consistent tension is virtually impossible to maintain.

The Cost of Instability: Failed Prints, Z-Wobble, and Constant Re-Leveling

The mechanical instability of flimsy stock springs sets off a chain of causation that negatively impacts print quality and increases required maintenance. Low-quality springs operate with lower preload tension, which means there is not enough static friction applied to the threads of the bed leveling knobs. Consequently, the vibration generated during high-speed printing can cause the adjustment knobs to self-rotate and loosen on their own, actively destabilizing the bed’s level over the course of a single print or a short series of prints.

This constant loss of leveling results in poor first-layer adhesion, warping, and inconsistent layer height (often termed Z-wobble), dooming a print right from the start. Upgrading to a much stiffer spring option is therefore not merely a convenience but a technical necessity; stiffer springs, such as the yellow die springs, provide more tension and are much stiffer than the stock alternatives. This fundamental shift to a component engineered for high mechanical demands immediately helps the 3D printer achieve much greater stability while printing, leading to less frequent re-leveling and a significantly higher rate of successful, high-quality prints. The use of a precision component effectively breaks the cycle of material failure leading to operator frustration.

Introducing the Industrial Workhorse: What Exactly is a Die Spring?

The yellow die spring is not simply a stiffer version of a generic compression spring; it represents an entirely different class of engineered component, originally designed for the extreme demands of industrial press machinery and stamping dies. This distinction is the source of its superior performance on a 3D printer bed.

Design and Geometry: The Advantage of Rectangular Wire

The fundamental technical distinction of a die spring is its wire cross-section. Unlike the rounded wire of standard springs, die springs are manufactured using a rectangular or trapezoidal wire cross-section with rounded corners. This specific geometry is the key to their immense power. The rectangular shape allows the spring to achieve a substantially higher spring rate and much greater load-bearing capacity within the exact same physical volume and working height compared to a round-wire spring. This geometric advantage is further compounded by a tighter winding, which inherently increases the spring rate regardless of the material used. These factors make all die springs inherently more powerful than generic compression springs, a vital element when seeking long-term stability in a 3D printer application.

The Material Difference: Chrome-Alloy, Heat-Treatment, and Fatigue Resistance

Die springs are crafted from high-grade materials specifically chosen for strength, durability, and resistance to fatigue and heat. While some versions are made from oil-tempered steel, the highest-quality die springs are fabricated from chrome-alloy steel, with premium versions using chrome silicon wire. The selection of this high-grade material is critical, offering enhanced wear and corrosion resistance over standard steel.

At Cixi Dili Spring Co., Ltd., we ensure that our manufacturing processes are as rigorous as the materials we use. After the wire is coiled into the desired shape, the springs undergo a critical heat treatment phase. This process, involving exposure to high temperatures followed by controlled cooling, is essential for refining the internal mechanical structure of the steel, significantly enhancing both strength and durability. Furthermore, top-grade die springs often receive surface treatments like shot peening and are preset (compressed beyond their yield point during manufacture) to ensure unsurpassed quality and maximum cycle life.

For the 3D printer environment, the thermal resistance of these materials is an essential advantage. Standard chrome-alloy steel is rated for maximum service temperatures of approximately 226 degrees Celsius (440 degrees Fahrenheit). This superior thermal threshold means that at the typical operating temperatures of a 3D printer heated bed (rarely exceeding 110 degrees Celsius), the die spring experiences virtually zero load loss due to thermal effects, maintaining its engineered force and stability far better than low-grade stock springs. This adherence to professional engineering standards (JIS, DIN, ANSI, ISO) is what allows Cixi Dili Spring Co., Ltd. to guarantee industrial-grade quality, whether the spring is destined for a complex industrial mould or a desktop 3D printer.

The Role of Ground Ends: Ensuring Perpendicular Load Distribution

Another subtle yet critical design feature of quality die springs is the finish of the end surfaces. High-quality die springs, including the yellow upgrade springs, feature flush or ground ends.

The purpose of a ground end is purely functional: it ensures that the spring load is evenly distributed at a perfect 90-degree angle to the contact surfaces (the heated bed and the mounting bracket/frame). In precision mechanics, force must be transmitted uniformly along the central axis of the spring. An unground or uneven end can cause non-uniform stress on individual coils and introduce a side-loading force, increasing the risk of spring buckling or binding. This side-loading would directly translate into a loss of leveling consistency. By providing a perfect, perpendicular load distribution, the ground ends of a die spring ensure that the high spring rate translates into maximum, stable vertical holding force, drastically improving the long-term reliability of the bed level.

The Yellow Enigma: Resolving the Industrial vs. Hobbyist Load Paradox

The term “Yellow Spring” has achieved almost legendary status in the 3D printing community as the go-to “Heavy Duty” upgrade. However, this perception presents a significant contradiction when viewed through the lens of industrial engineering standards. Resolving this “Yellow Paradox” is essential for a nuanced understanding of the component.

Clarifying the Standards: JIS B 5012 and the True Meaning of Yellow

Within the formal Japanese Industrial Standard (JIS B 5012) for die springs, which defines a color-coding system based on load capacity and deflection, the Yellow-colored spring (SF/SFR series) is officially designated as the Lightest Load or Extra Light Duty compression spring.

This industrial designation is often a major source of confusion for hobbyists who perceive the spring as “heavy-duty.” To complicate matters further, there is no universal, globally enforced color-coding standard across all spring manufacturers, though many adhere to established standards like JIS or ANSI. Some non-standard manufacturers, for example, have adopted color codes where Yellow indicates an Extra Heavy Load. As a manufacturer that adheres to strict international engineering standards, Cixi Dili Spring Co., Ltd. confirms that the Yellow die springs manufactured for high-precision industrial tooling are indeed rated for the lowest load capacity within the high-strength die spring family.

The Perception Shift: Why ‘Light Load’ Die Springs Feel ‘Heavy-Duty’ on a 3D Printer

The perceived “heavy-duty” nature of the yellow spring within the 3D printing community is entirely a matter of relative performance. The performance baseline for the hobbyist is the stock compression spring—a low-grade component with a negligible spring rate.

The industrial Yellow Die Spring, even as the “Light Load” member of its family, is manufactured using high-grade rectangular-section chrome alloy steel, giving it a spring rate that is exponentially greater than a generic, round-wire stock spring. Consequently, even the “Light Load” yellow die spring is dramatically stiffer and requires significantly more force to compress than an ordinary stock spring. The result is that the Yellow die spring is the lowest-performing spring in a heavy industrial context, yet it is an overwhelming high-performance upgrade in the context of a desktop 3D printer. This transparency establishes the spring’s true engineered value.

Comparative Spring Rates: Quantifying the Stiffening Effect

To place this component correctly, it is helpful to look at the maximum suggested deflection for different load ratings, which governs their intended use and cycle life.

| Color | JIS B 5012 Standard (Industrial Die Spring Family) | Alternative Standard (Example: Non-JIS/ANSI) | 3D Printer Context (Relative to Stock Spring) | Typical Max Deflection (Industrial) |

|---|---|---|---|---|

| Yellow (SF/SFR) | Lightest Load / Extra Light Duty | Extra Heavy Load | The Primary Stiff Upgrade | 50% (LD/Blue is sometimes used for Light Duty) |

| Blue (SL/SLR) | Light Load | Medium Load | A Stiffer, Higher-Load Alternative | 40% |

| Red (SM/SMR) | Medium Load | Heavy Load | Very High-Load/Rigid Upgrade | 32% |

| Green (SH/SHR) | Heavy Load | Low Load | Potential for Over-Rigidity/Safety Concerns | 24% (XHD) |

The industrial spring selection process mandates that springs be operated within strict deflection limits to achieve their rated service life. For Light Duty (often Yellow or Blue), the suggested maximum deflection can be around 50% of the free length. Crucially, the stiffness of this Yellow die spring, designed for high-force applications, is still orders of magnitude greater than the soft, unrated stock spring. This application of an industrial-grade “Light Load” component to a low-load scenario (the 3D printer bed) results in a massive performance over-engineering that translates directly into long-term, extreme reliability for the end-user. The die spring, fundamentally designed as a precision component for high-frequency cycling and controlled deflection, is vastly superior for maintaining a long-term stable bed level.

Critical Specifications for 3D Printer Compatibility and Performance

For an upgrade to be effective, the spring must not only be technically superior but also perfectly compatible with the existing printer hardware. The 3D printing community has converged on specific dimensions for the yellow die spring upgrade, largely due to the standardization of the most popular machines.

Standard Dimensions: The Universal 8mm OD x 4mm ID Fitment

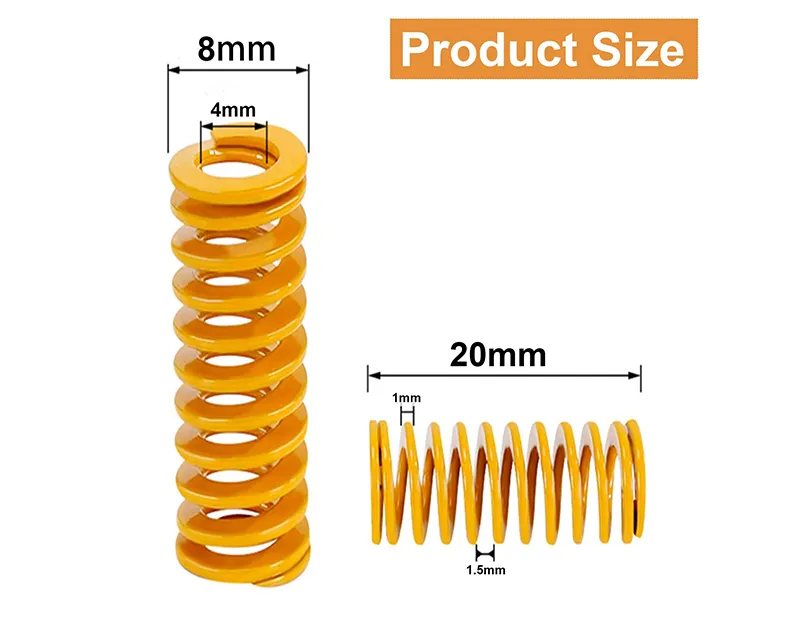

The most common and highly compatible specifications for the yellow die spring used across most desktop printers (such as the Creality Ender 3/Pro/V2/Max and the CR-10 series) are an Outer Diameter (OD) of 8mm (0.31 inches) and an Inner Diameter (ID) of 4mm (0.16 inches).

This specific sizing is engineered to ensure a direct, snug fit over the M4 leveling screws (M4 screws have a diameter of 4mm) used to mount the heated bed. This close fitment is vital because it provides proper guidance for the spring. In spring engineering, proper guidance (by a guide rod or a bored pocket) is crucial to reduce the chance of spring buckling under compression, a principle that is fundamental to the reliable function of all die springs. The 4mm ID effectively uses the leveling screw as a guide rod, maximizing stability and service life.

Choosing the Right Length: 20mm vs. 25mm and Z-Axis Considerations

The upgrade springs are typically available in two frequently used lengths: 20mm (0.78 inches) and 25mm (0.98 inches). The choice of length involves a critical trade-off directly related to the required Z-axis adjustment.

A longer spring, such as the 25mm version, will operate with a greater initial preload for the same desired bed height compared to a 20mm spring. This higher preload means greater tension, which further reduces the chance of the adjustment knobs vibrating loose. However, this longer length also pushes the heated bed further away from the printer’s frame, potentially necessitating a more significant physical or positional adjustment to the Z-limit switch or endstop. A shorter spring may be the preferred choice for printers with limited vertical Z-axis movement or for users who employ a thicker build plate (like a glass bed) which already consumes some Z-axis height.

The table below provides a comprehensive comparison of the key specifications that define the superiority of the yellow die spring upgrade.

| Specification | Stock 3D Printer Springs (Typical) | Yellow Die Springs (Standard Upgrade) | Engineered Benefit |

|---|---|---|---|

| Industrial Load Rating | Unrated / Very Low Grade Compression | Light Load (Industrial Grade) | Dramatically higher spring rate and force for stability. |

| Typical Dimensions (OD x ID x L) | Varies, often ≈ D8mm x D4mm x L25mm | D8mm x D4mm x L20/25mm | Consistent, standardized fitment for stability and guidance. |

| Material | Low-Carbon/Standard Spring Steel | High-Quality Chrome Alloy/Silicon Alloy Steel | Superior fatigue resistance and minimal load loss under heat. |

| End Surface | Often non-flat or rough | Ground/Flush Surfaces | Even and perpendicular load distribution, reducing binding and wobble. |

| Max Service Temperature | Low/Unknown | ≈ 226°C (440°F) for Chrome Alloy | No measurable stress relaxation at typical heated bed temperatures (<110°C). |

The convergence on specific die spring dimensions (8mm OD, 4mm ID, 20-25mm L) is highly advantageous. It allows Cixi Dili Spring Co., Ltd. to apply its industrial-grade, high-volume, precision manufacturing capabilities—including the use of rectangular wire, chrome-alloy material, and meticulous heat-treatment—to a high-volume consumer product, ensuring the best cost-to-performance ratio and guaranteeing a reliable, direct upgrade for the largest base of printer users.

Mastering the Upgrade: Installation, Preload, and Long-Term Stability

Installing an industrial-grade die spring is not a simple component swap; it requires adherence to proper industrial protocol, particularly concerning the initial setup of the Z-axis and the application of spring preload.

The Critical Step: Adjusting the Z-Limit Switch

Due to the inherent stiffness and, in some cases, the greater free length of the yellow die springs compared to the old stock springs, simply swapping them out will usually result in a new problem: the extruder nozzle will sit too low relative to the bed, causing a crash or failure to home properly. This happens because the stiffer springs resist compression more effectively and hold the bed in a higher resting position.

The necessary mechanical adjustment involves moving the Z-limit switch (endstop) or adjusting the Z-sensor offset. The switch must be loosened and moved upward relative to the Z-axis gantry to accommodate the bed’s new, higher resting position under optimal compression. A recommended procedure involves:

- Installing the springs and fully compressing the bed with the leveling knobs.

- Auto-homing the printer (the Z-limit switch will be triggered).

- Adjusting the Z-limit switch mounting position upward until the nozzle is sufficiently clear of the bed surface.

- Then, loosening the leveling knobs to achieve the necessary clearance for final bed tramming.

The use of an adjustable Z-limit switch mount, which can be custom-printed or purchased, greatly simplifies this fine-tuning process, making future adjustments for different build plates (e.g., glass vs. flexible PEI) far easier.

The Science of Set-Up: Achieving Optimal Spring Preload

The most crucial step in the upgrade process is ensuring the springs are properly preloaded. Preload, in an industrial context, is the initial compression force applied to the spring in the assembled tool before it performs any primary work. In the 3D printer application, proper preload ensures the springs are under continuous active tension at all times, which is the primary mechanism for preventing the adjustment knobs from vibrating loose.

The engineering rationale is derived from Hooke’s Law: by significantly compressing the spring (increasing the distance x), a significant restoring force (F) is created due to the high spring constant (k) of the die spring. This constant, powerful upward force acts against the threads of the leveling screw and knob, creating the static friction necessary to resist machine vibration and hold the level setting permanently. A widely accepted best practice involves first tightening all bed leveling knobs until the springs are moderately compressed (snug or firm), and then loosening each knob by two full, identical turns. This technique ensures consistent tension across all four corners, establishing the required preload and reducing the possibility of shock loading.

Troubleshooting: Dealing with Spring Buckling and Binding

The concepts of preload and guidance are directly lifted from industrial die spring application guides. While die springs are built for high loads, certain operational limits must be observed to maximize service life. Spring buckling, which is the sideways collapse of the spring, is a risk if the spring’s free length is more than four times its mean diameter. Since the small 3D printer springs typically fall well within this safe ratio and are guided by the leveling screw, the risk is minimal. However, it is essential to avoid solid height, where the coils touch. Compressing the spring to solid height causes permanent damage and stress relaxation. Sticking to the suggested deflection limits for the specific load rating (e.g., 50% for Light Load) is key to ensuring the maximum possible cycle life, often measured in millions of cycles.

Springs, Spacers, or Solid Mounts: A Comparative Analysis for Ultimate Rigidity

Once a 3D printer is equipped with an Automatic Bed Leveling (ABL) sensor, some users explore alternatives to springs, such as silicone spacers or solid mounts. An engineered comparative analysis reveals that the yellow die spring occupies an optimal middle ground.

The Case for Springs: Safety, Thermal Expansion Compensation, and Flexibility

The key advantage of any spring system over a completely rigid mount is its role as a critical mechanical safety buffer. In the event of a Z-axis crash—caused by a software error, an incorrect Z-offset calculation, or an ABL sensor failure—the springs compress, acting as a shock absorber. This momentary compression absorbs the impact energy and prevents potentially catastrophic damage to the extruder nozzle, the heated bed surface, and the linear motion components of the gantry.

Furthermore, springs allow the heated bed, which physically expands when heated, to move and settle slightly. This compliance is essential for compensating for minor thermal expansion and non-flatness, ensuring that the ABL sensor’s mesh is accurate and the bed is not unduly stressed by rigid mounting during the heating process. The Yellow Die Spring upgrade delivers high-level rigidity while retaining the necessary mechanical compliance for safety and thermal compensation—the optimal engineered solution for reliability.

The Silicone Spacer Alternative: Pros, Cons, and Long-Term Deformation Concerns

Silicone spacers and solid standoffs provide a very rigid platform and, when installed correctly, can lead to extremely infrequent re-leveling, sometimes even less than with stiff springs. The primary disadvantage, however, is the complete elimination of the safety buffer; a Z-axis crash will transmit its full force into the machine’s components.

More critically, high-grade steel is superior to elastomers (silicone) in long-term material stability under constant load and thermal cycling. Elastomers can be susceptible to a phenomenon called creep (or permanent deformation). Under constant compressive load and exposure to the heated bed temperature, the silicone may slowly lose its effective height, potentially requiring re-adjustment or replacement after prolonged use. While high-quality silicone spacers can be durable, the fatigue and load loss characteristics of high-grade, chrome-alloy steel under typical 3D printing conditions are demonstrably superior and quantifiable, minimizing the risk of long-term material failure that would necessitate re-leveling. For a professional-grade, multi-year installation, the engineered steel die spring offers a reliable solution that eliminates the long-term degradation risks associated with polymer-based alternatives.

Precision Engineered: Partnering with Cixi Dili Spring Co., Ltd. for Unwavering Quality

The quality and performance of the yellow die spring upgrade are a direct consequence of the industrial engineering principles applied during their manufacture.

Our Heritage of Excellence: Since 1995, Driving Global Spring Manufacturing

Cixi Dili Spring Co., Ltd. was established in 1995, building a nearly three-decade legacy focused exclusively on the precision manufacturing of high-performance spring components. Our dedication to engineering excellence allows us to serve critical industries globally, exporting a comprehensive range of products, including specialized Mould Springs (JIS Japanese Standard, US Standard), Torsion Springs, Compression Springs, Extension Springs, Music Wire Springs, and intricate Custom-shaped Springs.

Our operational structure is built around a complete system of Research and Development (R&D), Production, and Sales. This full-spectrum capability allows Cixi Dili Spring Co., Ltd. to control the quality of every spring from the moment the high-grade raw material (such as chrome silicon wire) is sourced, through coiling and heat treatment, to final quality assurance. This rigorous process ensures that every product adheres to the highest standards for fatigue and thermal resistance, a necessary quality regardless of whether the spring is for an industrial car component or a desktop 3D printer.

Beyond 3D Printing: Custom Solutions Across Automotive, Electronic, and Industrial Machinery

While the yellow die spring provides a significant performance enhancement for the desktop community, our core expertise lies in manufacturing critical, high-stress components for a wide array of industrial applications. Our springs are essential in:

- Mould Tooling: Supplying die springs that must meet the rigorous cycle-life and load requirements of the JIS and DIN standards for stamping and forming.

- Automotive: Manufacturing custom compression and torsion springs for demanding, safety-critical vehicle components.

- Industrial Machinery: Providing high-force extension and custom springs for heavy-duty equipment and industrial processing lines.

We rigorously execute all manufacturing processes according to strict international engineering standards, including JIS, DIN, ANSI, and ISO, as well as individual client-specific tolerances. This commitment to quantified, professional manufacturing means that the yellow die spring used in a 3D printer benefits from the exact same quality control and material specifications as the springs we supply to multi-million-dollar industrial presses.

Your Blueprint, Our Expertise: Custom Manufacturing Based on Samples or Drawings

We recognize that not all applications can be satisfied by standard, off-the-shelf components. Many high-performance spring requirements—whether for a novel robotic mechanism, a new printer design, or a unique industrial jig—demand custom specifications. Cixi Dili Spring Co., Ltd. is committed to being a full-service engineering partner. We proudly support personalized production based on customer samples or technical drawings. If your project requires a non-standard spring—perhaps a unique load rating, an unusual shape (Custom-shaped Springs), or a specific high-tension material like Music Wire Springs—our R&D and manufacturing capacity is equipped to deliver a precise, tailored, high-precision solution.

Conclusion: The Foundation of Flawless Prints

The choice of a bed leveling spring is a choice between a consumer-grade compromise and industrial-grade reliability. The Yellow Die Spring upgrade represents the professional, engineered solution to the universal problem of bed instability. Its superiority is founded on three critical engineering pillars: the geometric advantage of the rectangular wire, the thermal and fatigue resistance of high-grade chrome-alloy steel, and the precision load distribution of its ground ends.

By adopting this industrial workhorse, enthusiasts secure the necessary preload to maintain level settings for longer print sessions and thousands of printing hours, eliminating the frustrating loop of thermal degradation, vibration, and constant re-leveling. Furthermore, the high-quality steel construction ensures the component retains its engineered integrity and serves as a vital mechanical safety buffer, a level of security that polymer alternatives cannot definitively guarantee over the long term. Upgrading to a die spring is a permanent investment in the stability, quality, and consistency of the 3D printing foundation. The key to success is ensuring the Z-axis compensation is correctly applied and the proper preload is achieved.

Contact Cixi Dili Spring Co., Ltd.

For custom spring solutions, high-volume production, or industrial-grade components built to international standards (JIS, DIN, ANSI, ISO), contact our team.

📧 Email: [email protected]

📱 WhatsApp: +86 13586942004

Frequently Asked Questions (FAQ)

Why are Yellow Die Springs called “Light Load” on the industrial scale if they are so much stiffer than my stock springs?

This apparent contradiction is a result of scaling. On the industrial JIS B 5012 standard, Yellow (SF/SFR) is the Lightest Load designation within the family of extremely powerful, high-force die springs. However, even the “lightest” industrial die spring is manufactured from high-grade, rectangular-wire alloy steel, giving it a spring rate that is exponentially higher than the cheap, round-wire stock springs originally supplied with most consumer 3D printers. Its perceived “heavy-duty” nature is purely a comparison relative to a very weak stock component.

Do I need to change my Z-limit switch or sensor when installing these springs?

Yes, adjustment of the Z-limit switch (endstop) or the Z-sensor offset is a critical, nearly universal requirement. Because the new, stiffer yellow springs are either slightly longer or resist compression more effectively, the heated bed will sit in a higher position than it did with the old springs. If the Z-limit switch is not raised (i.e., moved upward on the Z-axis gantry), the nozzle will likely crash into the bed or the printer will fail to home correctly. It is essential to accommodate the bed’s new resting height to achieve proper preload.

Will these springs degrade or lose force over time due to the heated bed?

No, not measurably within the operating range of a 3D printer. High-grade die springs are manufactured from chrome-alloy or chrome-silicon steel, materials engineered for use in high-stress, high-cycle industrial machinery. This material is rated for maximum service temperatures of approximately 226 degrees Celsius (440 degrees Fahrenheit). Since a typical heated bed rarely exceeds 110 degrees Celsius, the spring operates well within its thermal stability window, virtually eliminating the stress relaxation and load loss experienced by low-grade stock springs.

How do Yellow Die Springs compare to Blue or Red die springs for my 3D printer?

Yellow die springs, being the “Light Load” of the die spring family, offer the ideal balance of high stiffness and adjustability for a desktop 3D printer. Blue (Light Load in the ANSI/US standard) and Red (Medium Load) die springs offer even higher load capacities. While these are technically stronger, they are often unnecessary and can make the leveling knobs extremely difficult to turn, requiring excessive force to fine-tune the bed level. The Yellow spring provides more than enough force to prevent knob self-loosening and provides superior fatigue resistance without requiring extreme physical effort to adjust.

Is it better to use silicone spacers instead of these die springs?

Silicone spacers (solid mounts) offer excellent rigidity and often reduce the need for leveling, but they are not without trade-offs. The primary drawback is the elimination of the mechanical safety buffer, increasing the risk of damage in a Z-axis crash. Furthermore, high-grade steel is superior to elastomers (silicone) in long-term material stability under heat and load. Silicone is susceptible to long-term creep (permanent deformation) under constant compression and thermal cycling, which is a risk that high-grade engineered steel components avoid entirely. The Yellow Die Spring offers the highest possible reliability without sacrificing the vital mechanical safety function.